Walk into a retail store, pick up a shipping package, or check in at a hospital, and chances are you’ve already held something printed by a thermal printers. From receipts and barcodes to wristbands and tickets, these devices quietly power many everyday processes without most people even realizing it. Unlike traditional printers that rely on ink or toner, thermal printers use heat to create sharp, fast, and reliable prints—making them indispensable in industries that demand efficiency and durability.

Over the past few decades, thermal printing technology has evolved from simple cash register receipts to complex, high-performance systems capable of handling logistics, healthcare, and large-scale industrial labeling. Their appeal lies in their simplicity: fewer moving parts, lower operating costs, and consistent results. But not all thermal printers are the same. From direct thermal to thermal transfer models, each type has unique strengths, weaknesses, and ideal applications.

This guide will break down everything you need to know about thermal printers—how they work, their features, benefits, limitations, and the industries that rely on them daily. Whether you’re running a business that needs fast label printing or exploring options for cost-effective point-of-sale solutions, understanding thermal printers will help you make smarter decisions.

What is a Thermal Printer?

At its simplest, a thermal printer is a device that prints using heat. Instead of spraying ink or transferring toner powder, it applies controlled heat to a paper surface or ribbon to produce text and images. This makes thermal printers unique: they don’t require messy refills of ink or toner and typically have fewer mechanical components, which leads to higher reliability and lower maintenance.

There are two main categories of thermal printers. Direct thermal printers apply heat directly to specially coated, heat-sensitive paper that darkens when exposed to the print head. They are widely used for receipts and shipping labels because they are fast and inexpensive, though the prints tend to fade over time.

Thermal transfer printers, on the other hand, use a ribbon coated with wax or resin. Heat melts the ribbon’s coating and transfers it onto paper or labels, resulting in more durable and long-lasting prints.

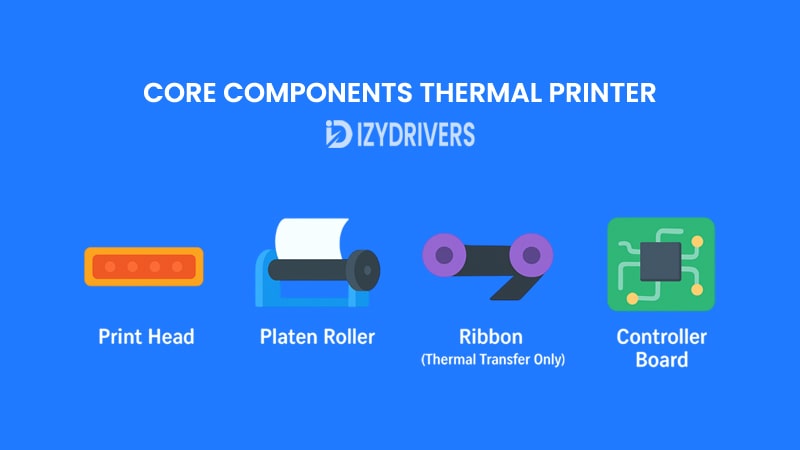

Core Components Thermal Printer You Should Know

To understand how a thermal printer works, it helps to break down the key components inside the printer machine. While thermal printers look compact from the outside, several carefully engineered parts work together to deliver fast, clean, and reliable prints. Each plays a vital role in ensuring smooth operation and consistent results.

1. Print Head

The print head is the most critical part of any thermal printer. It contains a series of tiny heating elements that activate whenever the printer receives a command. These elements apply precise bursts of heat, either directly onto heat-sensitive paper in a direct thermal printer or onto a ribbon in a thermal transfer printer. The quality and sharpness of your prints depend heavily on the condition of the print head. A worn or dirty print head can lead to faded images, uneven barcodes, or blank spots, which is why regular cleaning and proper maintenance are essential.

2. Platen Roller

Opposite the print head is the platen roller, a durable rubber roller that presses the paper or label firmly against the heating elements. This pressure ensures that the heat is transferred evenly and consistently. Without the platen roller, paper might slip or shift during printing, resulting in misaligned text or barcodes. Over time, platen rollers can wear out or accumulate dust and adhesive from labels, which may cause paper jams or poor print quality. Routine inspection helps maintain its effectiveness.

3. Ribbon (Thermal Transfer Only)

In thermal transfer printers, a ribbon coated with wax, resin, or a combination of both acts as the medium for printing. When heated by the print head, the ribbon melts and bonds with the paper surface, creating prints that are highly durable and resistant to heat, chemicals, and abrasion. Choosing the right ribbon material is crucial—wax ribbons are affordable but less durable, while resin ribbons provide maximum resistance but at a higher cost.

4. Controller Board

Behind the scenes, the controller board functions as the printer’s “brain.” It manages everything from the temperature applied by the print head to the speed at which the paper feeds through the rollers. It also processes incoming data, converting digital commands into precise physical actions. Without a well-calibrated controller board, the printer would not be able to maintain consistent print quality or adapt to different media types.

Together, these components form the backbone of thermal printer technology. The print head delivers precision, the platen roller ensures stability, the ribbon provides durability (in transfer models), and the controller board ties everything together. Understanding their roles not only helps you operate the printer more effectively but also makes troubleshooting and maintenance much easier.

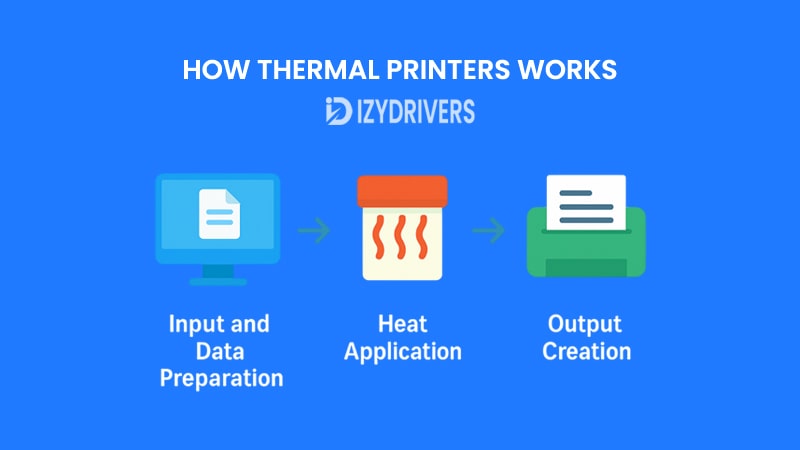

How Thermal Printing Works

The process of thermal printing may sound complex, but at its heart, it’s about using heat to make images appear on paper. The workflow can be broken down into three essential stages: preparing the data, applying heat through the print head, and producing the final output.

Step 1: Input and Data Preparation

Like any printer, a thermal printer receives commands from a computer or device. The data is translated into instructions that tell the print head when and where to apply heat. This ensures that barcodes, text, or images appear exactly as intended.

Step 2: Heat Application

The paper (or label) is fed between the print head and the platen roller. The printer then applies precise bursts of heat:

- In direct thermal printing, the heat activates a chemical coating on the paper, turning it dark where needed.

- In thermal transfer printing, the heat melts ink from a ribbon, bonding it permanently to the surface.

Step 3: Output Creation

As the paper moves through, the controlled heat produces sharp, clean results almost instantly. Unlike inkjet printers that must dry ink or laser printers that use toner fusing, thermal printing requires no extra steps.

This streamlined process means thermal printers can operate faster, with fewer jams and lower costs. It also makes them highly reliable in environments where speed and precision are critical, such as retail checkout counters, warehouses, and healthcare facilities.

Types of Thermal Printers

Although thermal printing technology may seem straightforward, it comes in two main variations, each designed to meet different needs. Understanding the differences between these types is essential before deciding which one works best for your business or personal use. Both Direct Thermal Printers and Thermal Transfer Printers share the same fundamental printing principles—using heat as the primary mechanism—but the way they apply heat and produce images differs significantly.

1. Direct Thermal Printers

Direct thermal printers are the simpler of the two categories. Instead of using ink, toner, or ribbons, they rely on special heat-sensitive paper that reacts when exposed to the printer’s heated print head. This reaction darkens the areas of the paper that come into contact with the heat, forming text, barcodes, or images.

Key Advantages:

- They are compact, cost-efficient, and require fewer consumables since no ribbon is needed.

- Maintenance is minimal, making them a favorite for high-volume, low-cost operations.

Common Use Cases:

Direct thermal printers are widely used in industries that require fast, short-term labels. Think of supermarket receipts, shipping labels, and event tickets. However, because the paper is heat-sensitive, prints can fade over time and are not ideal for environments exposed to heat, sunlight, or chemicals.

2. Thermal Transfer Printers

Thermal transfer printers use a ribbon coated with wax, resin, or a combination of both. During printing, heat from the print head melts the ribbon’s coating, which bonds permanently to the label or paper surface. This results in images and barcodes that are more durable and resistant to external factors.

Key Advantages:

- They produce long-lasting prints resistant to abrasion, UV light, and chemical exposure.

- They are versatile, working on a wide range of materials beyond paper, such as polyester, polypropylene, and even synthetic labels.

Common Use Cases:

Thermal transfer printers are commonly found in industries that demand durable labeling solutions. They’re used for asset tags, laboratory samples, outdoor product labeling, and compliance labeling in logistics or manufacturing.

Comparing Direct Thermal vs Thermal Transfer Printers

The choice between direct thermal and thermal transfer printing ultimately depends on your needs. Direct thermal is perfect for quick, disposable prints where longevity is not an issue, while thermal transfer excels in applications requiring durability and resistance.

| Feature / Aspect | Direct Thermal Printers | Thermal Transfer Printers |

|---|---|---|

| Printing Method | Uses heat-sensitive paper that darkens when exposed to heat. | Uses a heat-applied ribbon (wax/resin) to bond images onto media. |

| Consumables Needed | Only thermal paper. | Requires ribbon + labels/media. |

| Print Durability | Short-term, prone to fading from heat, light, or friction. | Long-lasting, resistant to abrasion, chemicals, and UV exposure. |

| Print Quality | Good for barcodes and receipts but limited lifespan. | Higher quality, crisp, durable prints on various materials. |

| Maintenance | Low, fewer moving parts, no ribbon handling. | Moderate, requires ribbon management and occasional adjustments. |

| Cost Efficiency | Lower upfront and operating costs, ideal for high-volume tasks. | Higher consumable costs due to ribbons but offers long-term value. |

| Common Applications | Receipts, shipping labels, tickets, temporary tags. | Asset tags, product labels, laboratory samples, compliance labels. |

| Best For | Short-term, disposable, low-cost printing needs. | Long-term, durable labeling in industrial or outdoor environments. |

Features and Benefits of Thermal Printers

Thermal printers have become an essential tool across industries because of their unique ability to deliver fast, high-quality prints without relying on ink or toner. Unlike traditional printers, they operate using heat, which simplifies the printing process and reduces the number of consumables required. Below, we’ll dive deeper into their standout features and the benefits they bring to everyday operations.

Key Features of Thermal Printers

1. High-Speed Printing

One of the most significant features of thermal printers is their speed. Because they don’t need to apply ink or wait for it to dry, thermal printers can generate labels, barcodes, or receipts almost instantly. This makes them invaluable in fast-paced environments like retail checkouts, logistics centers, and healthcare facilities.

2. Compact and Lightweight Design

Most thermal printers are designed to be small and portable, making them easy to fit into tight workspaces or carry on the go. Portable thermal printers, for example, are widely used in delivery services to issue receipts at the customer’s doorstep.

3. Quiet Operation

Thermal printers produce far less noise compared to dot matrix or even some inkjet printers. This quiet operation improves workplace environments, especially in settings like hospitals, offices, and libraries where noise reduction is important.

4. Simple Mechanism with Fewer Parts

Because they use heat instead of complex ink systems, thermal printers have fewer moving parts. This not only reduces the chance of mechanical failure but also makes them easier to maintain and more reliable over time.

Key Benefits of Using Thermal Printers

1. Lower Operating Costs

With no ink cartridges or toner to replace, the ongoing expenses of thermal printing are significantly reduced. Consumables are limited mainly to paper or ribbons (for transfer printers), which makes them more cost-effective for high-volume operations.

2. Superior Print Clarity

Thermal printing produces sharp, smudge-free images that are easy to scan and read. This is particularly beneficial for barcodes, shipping labels, and medical wristbands, where accuracy and readability are critical.

3. Durability and Reliability

Thermal printers are built to withstand heavy usage. Their robust design ensures they can operate consistently, even in demanding environments like warehouses or outdoor facilities. Thermal transfer printers, in particular, provide prints that resist chemicals, UV exposure, and abrasion.

4. Versatility Across Applications

From printing shipping labels to producing wristbands in hospitals, thermal printers are used in countless industries. Their ability to handle a wide range of media makes them highly adaptable.

By combining speed, cost savings, reliability, and durability, thermal printers stand out as a powerful solution for businesses of all sizes. Whether you’re running a retail shop that needs receipts or a manufacturing plant that requires long-lasting product labels, the features and benefits of thermal printers make them a dependable choice for modern printing needs.

Industry Applications of Thermal Printers

Thermal printers are far more than simple receipt machines; they are versatile tools used across multiple industries where speed, reliability, and precision are crucial. From retail and logistics to healthcare and manufacturing, these printers provide tailored solutions that improve workflow efficiency and reduce errors.

1. Retail and Point-of-Sale (POS)

In retail environments, thermal printers are the backbone of fast and accurate transaction processing. They print receipts, barcodes, and price tags with high speed and clarity, enabling smoother customer checkouts. Direct thermal printers are often preferred for short-term receipts, while thermal transfer printers are used for durable tags or labels.

Example: Supermarkets, convenience stores, and clothing retailers rely on these printers to generate receipts instantly and ensure product barcodes are readable at the checkout counter.

2. Logistics and Shipping

Shipping labels and package tracking rely heavily on thermal printing technology. Durable, scannable barcodes and shipping labels are essential for accurate delivery and inventory management. Thermal transfer printers are particularly suited for this sector because they produce long-lasting labels that withstand handling, moisture, and exposure to sunlight.

Example: Courier companies like FedEx and UPS use industrial thermal printers to generate shipping labels that remain intact throughout transit.

3. Healthcare

Thermal printers play a critical role in hospitals, laboratories, and pharmacies. They produce patient wristbands, prescription labels, specimen labels, and more, where accuracy can directly impact patient safety. The speed and reliability of thermal printing help medical staff save time and reduce errors.

Example: Hospitals use direct thermal printers to quickly generate patient ID bands, while laboratories rely on thermal transfer printers for durable sample labels.

4. Manufacturing and Inventory Management

In factories and warehouses, thermal printers are essential for asset tracking, product labeling, and compliance tags. They ensure that items can be quickly identified and scanned throughout the supply chain, improving efficiency and reducing the risk of lost inventory.

Example: Electronics manufacturers use thermal transfer printers to label components, while warehouses print durable barcoded labels for pallets and shipping containers.

5. Entertainment and Event Management

Thermal printers also find applications in ticketing for concerts, movies, and events. The speed and accuracy of thermal printing make it ideal for high-volume scenarios where queues need to move quickly.

Example: Movie theaters, sports arenas, and concert venues use portable or desktop thermal printers to issue tickets instantly while maintaining barcode readability for entry scanning.

By serving a wide range of industries, thermal printers demonstrate their flexibility and importance in modern business operations. Their ability to handle both short-term and long-lasting printing needs makes them a go-to solution for companies that require precision, speed, and durability.

Maintenance & Troubleshooting Tips for Thermal Printers

Thermal printers are designed for reliability, but like any mechanical device, they require proper maintenance to perform consistently over time. Neglecting routine care can lead to paper jams, faded prints, or equipment downtime. Below are expert-recommended tips to keep your thermal printer running smoothly.

1. Regular Cleaning of Print Head and Rollers

The print head is the most critical component of a thermal printer, responsible for transferring heat to paper or ribbons. Over time, dust, adhesive residues, or label particles can accumulate, reducing print quality. Use a lint-free cloth or a manufacturer-approved cleaning pen to gently wipe the print head.

The platen roller also collects dust and debris, which can lead to misfeeds or uneven printing. Cleaning the roller with a soft cloth and isopropyl alcohol regularly helps maintain smooth paper movement and consistent pressure.

2. Using High-Quality Consumables

Always use compatible thermal paper and ribbons. Poor-quality paper or ribbons can leave residue on the print head, reduce print clarity, and increase wear on the rollers. Thermal transfer printers, in particular, benefit from premium wax or resin ribbons, which improve durability and longevity of the printed material.

3. Proper Paper Handling and Storage

Thermal paper is sensitive to heat, light, and moisture. Store paper in a cool, dry place away from direct sunlight to prevent premature darkening or curling. Avoid touching the printing surface with bare hands, as oils and dirt can interfere with print quality.

4. Routine Calibration and Firmware Updates

Many thermal printers allow for calibration of print head pressure, temperature, and alignment. Regular calibration ensures that barcodes, labels, and text are crisp and accurately positioned. Firmware updates from the manufacturer can improve performance, fix bugs, and enhance compatibility with software systems.

5. Troubleshooting Common Issues

| Issue | Possible Cause | Quick Fix |

|---|---|---|

| Faded or uneven prints | Dirty print head or low-quality paper | Clean print head; use recommended paper/ribbons |

| Paper jams | Misaligned or stuck paper | Remove jam carefully; check roller and paper tray alignment |

| Smudged prints | Platen roller or ribbon issues | Clean rollers; replace worn ribbon |

| Double-feeding | Worn feed rollers | Inspect and replace feed rollers if necessary |

| Printer not recognized | Connection or driver issue | Check USB/Bluetooth/Wi-Fi; reinstall drivers |

Proper maintenance not only extends the life of your thermal printer but also ensures consistent, high-quality output. By following these tips and monitoring key components regularly, you can prevent common problems and reduce downtime.

Thermal Printers vs. Other Printer Types

Thermal printers are highly specialized, excelling in speed, durability, and efficiency, particularly for labels, receipts, and barcodes. However, different types of printer technologies have their own strengths. Understanding the distinctions helps businesses choose the right printer for each task.

vs. Laser Printers

Laser printers are known for high-speed, high-resolution document printing, often in color, making them ideal for office reports and brochures. However, thermal printers outshine laser printers when it comes to printing receipts, barcodes, or labels quickly and reliably. Thermal printers require fewer consumables—direct thermal models need only paper, eliminating toner cartridges—and produce less heat, which allows continuous printing without the risk of paper curling.

Example: Retail stores prefer thermal printers for receipts, while laser printers are reserved for internal office document printing.

vs. All-in-One Printers

All-in-one printers combine printing, scanning, copying, and sometimes faxing. While versatile, they are slower and less reliable for continuous label or receipt printing. Thermal printers, by focusing solely on printing, offer higher speed, less downtime, and fewer maintenance issues.

Example: A warehouse may use an all-in-one printer for occasional shipping labels, but a thermal printer is essential for high-volume daily operations.

vs. Inkjet Printers

Inkjet printers produce high-quality images and full-color documents, but they are slower and require frequent cartridge replacement. Thermal printers, especially direct thermal, do not use ink, making them more cost-effective and less prone to smudging. Inkjet is ideal for photos or color graphics, but thermal printers are better for barcodes, shipping labels, and receipts that need to be durable and readable.

Example: Shipping departments often choose thermal printers over inkjets for their speed and reliability.

vs. Photo Printers

Photo printers focus on producing vibrant, high-resolution images on photo paper. Thermal printers cannot match this level of color fidelity or resolution. However, they are far superior for text-based printing, labels, and barcode scanning where clarity and speed matter more than color accuracy.

Example: Ticketing systems at cinemas or events use thermal printers for black-and-white tickets, while photo printers are used for souvenirs or professional photo printing.

vs. Dot Matrix Printers

Dot matrix printers can handle multipart forms and carbon copies, making them useful for invoicing and some industrial applications. However, they are noisier, slower, and produce lower-quality prints. Thermal printers are quieter, faster, and provide clearer text and barcodes, which is critical for retail, logistics, and healthcare industries.

Example: Hospitals may still use dot matrix for some administrative forms but rely on thermal printers for patient wristbands and prescription labels.

vs. 3D Printers

3D printers create three-dimensional objects, while thermal printers are designed for two-dimensional text, labels, and barcodes. Although both are specialized, their applications are completely different. Thermal printers excel in speed and efficiency for labels and receipts, whereas 3D printers are used for prototyping, manufacturing parts, and creating physical objects.

Example: A logistics company prints thousands of shipping labels daily using thermal printers, while a product design studio uses a 3D printer for prototyping parts.

vs. Portable Printers

Some portable printers are thermal-based, but not all are designed for industrial durability. Standard thermal printers (desktop or industrial models) offer faster printing, longer life, and higher volume capabilities compared to many portable models, which prioritize mobility over speed or volume.

Example: Delivery drivers may carry a portable thermal printer for receipts on-the-go, but a warehouse uses stationary thermal printers to handle hundreds of labels per hour.

Comparison Thermal Printers vs Other Printers

| Printer Type | Key Advantages of Thermal Printers | Limitations Compared to Thermal Printers | Ideal Applications |

|---|---|---|---|

| Laser Printers | Faster label/receipt printing; fewer consumables for direct thermal | Laser printers better for full-page, color documents | POS receipts, barcodes |

| All-in-One Printers | Dedicated labels/tickets; simpler maintenance | All-in-one printers are versatile but slower for labels | Retail labels, tickets |

| Inkjet Printers | No ink needed (direct thermal) or low ribbon usage | Inkjet excels in high-resolution color prints | Shipping labels, receipts |

| Photo Printers | Fast, reliable black-and-white prints | Photo printers superior for color images and photos | Ticketing, ID wristbands |

| Dot Matrix Printers | Quieter, faster, less paper jams for certain tasks | Dot matrix better for multipart forms | Continuous labels or multipart forms |

| 3D Printers | Immediate print output for barcodes/labels | 3D printers for objects; thermal printers for labels/text | Retail, logistics |

| Portable Printers | High speed, durable prints in industrial or mobile use | Some portable printers are thermal-based, but less robust | Delivery receipts, on-the-go labels |

Key Takeaways

- Speed and Reliability: Thermal printers outperform most general-purpose printers in generating labels, receipts, and barcodes quickly and consistently.

- Durability: Thermal transfer models produce prints resistant to abrasion, chemicals, and UV light—something laser or inkjet printers cannot match for specialized applications.

- Maintenance: Fewer moving parts in thermal printers translate into lower maintenance requirements compared to inkjet, laser, or dot matrix printers.

- Specialization vs Versatility: While other printers offer more versatility (color printing, full-page documents), thermal printers specialize in precise, fast, and long-lasting small-format printing.

Buying Guide: Choosing the Right Thermal Printer

Choosing the right thermal printer is critical for ensuring efficiency, reliability, and cost-effectiveness in your operations. While all thermal printers use heat to produce images, their features, capabilities, and price points can vary significantly. Below is a step-by-step guide to help you make an informed decision.

Identify Your Printing Needs

Start by understanding the specific requirements of your business or application:

- Volume: How many labels, receipts, or tickets will you print daily or monthly?

- Media Type: Do you need to print on standard paper, labels, wristbands, or synthetic materials?

- Print Longevity: Will the prints be short-term (receipts) or long-lasting (asset labels)?

Knowing these details will guide you toward the right type of thermal printer and prevent overspending on unnecessary features.

Choose Between Direct Thermal and Thermal Transfer

- Direct Thermal Printers: Ideal for short-term labels and receipts. They are fast, cost-efficient, and low-maintenance but prints fade over time.

- Thermal Transfer Printers: Better for durable, long-lasting labels. They handle a wide range of media but require ribbons, which increase operating costs.

Consider Print Speed and Volume Capacity

Thermal printers differ in how quickly they can print and how many pages or labels they can handle per month:

- Low-volume users: Desktop direct thermal printers are sufficient.

- High-volume users: Industrial or commercial thermal transfer printers with higher speed and duty cycles are essential.

Faster printers save time and improve productivity, especially in busy retail, logistics, or healthcare environments.

Connectivity and Software Compatibility

Modern thermal printers offer various connectivity options: USB, Ethernet, Wi-Fi, or Bluetooth. Choose a printer compatible with your devices and software systems. Some printers also provide mobile printing capabilities via apps, which is useful for field operations.

Evaluate Maintenance and Ease of Use

Printers with easy-access print heads, roll replacement, and cleaning features reduce downtime. Look for models with clear indicators for paper or ribbon status and simple user interfaces for routine maintenance.

Total Cost of Ownership (TCO)

Consider not only the purchase price but also long-term costs:

- Cost of paper, ribbons, or labels

- Maintenance and replacement parts

- Energy efficiency

- Printer lifespan and warranty coverage

Investing slightly more upfront in a high-quality printer can save money over time by reducing consumable costs, downtime, and repairs.

Read Reviews and Assess Customer Support

Before purchasing, research customer reviews to see how printers perform in real-world conditions. Reliable customer support, spare part availability, and firmware updates are crucial for avoiding long-term operational issues.

By carefully evaluating your printing needs, choosing the appropriate thermal printer type, and considering total cost of ownership, you can select a printer that maximizes efficiency, durability, and return on investment.

Conclusion

Thermal printers are more than just machines that print receipts or labels—they are critical tools that drive efficiency across industries. Their unique heat-based printing technology allows for fast, reliable, and durable output, making them ideal for retail, logistics, healthcare, manufacturing, and entertainment sectors.

By understanding the differences between direct thermal and thermal transfer printers, knowing their key features, and maintaining them properly, businesses can maximize performance and minimize downtime. Whether you need short-term receipts, long-lasting asset labels, or portable on-the-go printing, thermal printers provide a specialized printer solution that balances speed, cost-effectiveness, and reliability. Investing in the right thermal printer ensures smooth operations, accurate tracking, and professional-quality prints every time.

FAQs About Thermal Printers

What is the difference between direct thermal and thermal transfer printers?

Direct thermal printers use heat-sensitive paper to produce short-term prints, while thermal transfer printers use a heated ribbon to create durable, long-lasting images on various media types.

Do thermal printers require ink or toner?

No, direct thermal printers do not require ink or toner. Thermal transfer printers use a ribbon instead of traditional ink to transfer images onto labels or paper.

How long do prints from a thermal printer last?

Direct thermal prints are best for short-term applications and may fade over weeks or months depending on exposure to heat and light. Thermal transfer prints are more durable and can last years in demanding environments.

Can thermal printers handle colored printing?

Thermal printers are primarily designed for black-and-white printing. While some thermal transfer ribbons allow for limited color printing, they are not suitable for high-resolution full-color images like inkjet printers.

Which industries benefit most from thermal printers?

Retail, logistics, healthcare, manufacturing, and entertainment are the main industries. Thermal printers excel in applications requiring fast, precise, and durable labels, receipts, or tickets.