Printers may look simple on the outside, but inside, there’s an entire network of mechanical and electronic parts working together to bring digital documents to life. For many users, understanding the parts of printer often happens only when something goes wrong—like a paper jam or low ink warning. Yet, knowing the printer parts and what they actually do can save time, money, and frustration.

Before you call for technical support or rush to replace a malfunctioning printer, a basic understanding of its components can help you troubleshoot issues yourself. From the exterior casing that keeps everything protected to the tiny nozzles responsible for precise ink placement, each part has a role to play. This guide takes you through all the parts of printer with their names and functions, explaining them in clear, simple terms so you can better appreciate how your machine works.

We’ll break down the printer parts into categories—from external panels to intricate internal mechanisms—so you can see exactly how they connect and operate. Whether you’re curious about the role of the print head, the importance of rollers, or the difference between an ink cartridge and a drum unit, this article will give you the answers in a way that’s easy to follow and practical to apply.

Overview of Printer Components

Before diving into individual printer parts, it helps to see the bigger picture. A modern printer is made up of several systems working together—mechanical components that handle paper movement, electronic circuits that control functions, and software layers that ensure your computer and printer speak the same language. Understanding these main parts of printer will make it easier to grasp how each piece contributes to the final print job.

Most printer parts can be grouped into three main categories: exterior components, interior mechanical components, and electronic or software-related parts. The exterior elements are what you interact with daily—things like the paper tray, control panel, and output area. The mechanical parts inside handle the physical process of feeding paper and applying ink or toner. Finally, the electronic and software parts manage instructions from your computer, telling the printer exactly what to do and when to do it.

These categories create a roadmap for exploring each section in detail. By breaking down the parts of printer this way, you’ll not only understand what each component does but also see how they work together to produce a clear, crisp printout.

Major Printer Parts and Their Functions

When we talk about printers, most people only think about paper trays and ink cartridges. But inside every device is a complex network of printer parts working together to deliver that final printout. To make sense of it all, let’s start by looking at the parts of printer in three main groups: exterior components, interior mechanical components, and electrical or software-related parts.

By understanding what each part does, you can better troubleshoot problems, maintain your machine, and even choose the right printer for your needs. Let’s begin with the parts you see and touch every day before moving deeper into the components hidden inside.

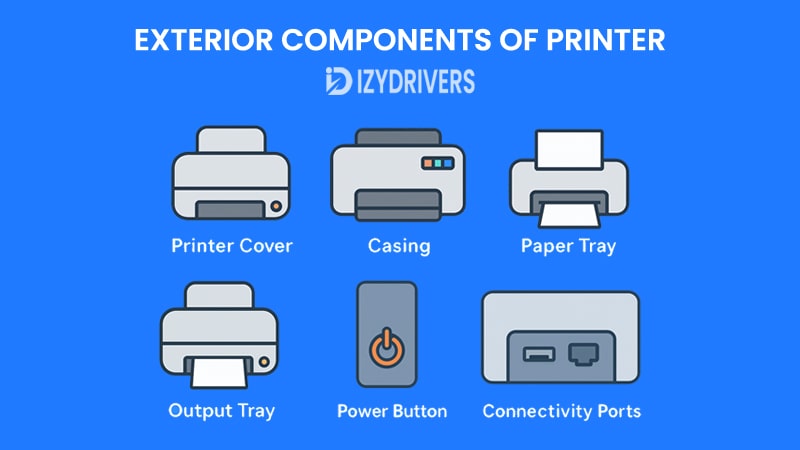

Exterior Components

The exterior printer parts are the first things users interact with. They might seem simple, but these parts of printer play a critical role in usability, organization, and even protecting the internal components.

Printer Exterior Parts: Names and Functions at a Glance

| Printer Part Name | Main Function | Why It Matters for Users |

|---|---|---|

| Printer Cover & Casing | Protects internal printer parts from dust, moisture, and damage | Keeps sensitive parts safe and improves printer lifespan |

| Paper Tray (Input Tray) | Holds and feeds blank sheets into the printer | Ensures smooth printing, prevents misfeeds and paper jams |

| Output Tray | Collects finished pages neatly | Keeps documents organized and prevents scattering |

| Control Panel & Display | User interface for settings, error alerts, and job control | Simplifies printer operation and troubleshooting |

| Power Button & Ports | Provides power and connectivity (USB, Ethernet, Wi-Fi) | Enables communication with devices and safe power use |

Now that you’ve seen the quick summary of all exterior printer parts and their key printer functions, let’s explore each component in detail to understand how it works and why it matters.

Printer Cover & Casing

At first glance, the printer cover—or casing—might look like nothing more than a plastic shell. But in reality, it serves several critical roles that go beyond appearances.

First and foremost, the casing protects the sensitive parts of printer inside. Components like the mainboard, print head, and power supply can easily be damaged by dust, humidity, or accidental spills. Without a sturdy cover, these hazards would significantly shorten the printer’s lifespan.

A well-designed casing also shields against physical damage. A bumped corner, a falling stapler, or even someone brushing against the printer in a busy office could easily harm delicate interior printer parts if they were exposed. The cover keeps everything safe, acting like a protective barrier.

Beyond functionality, the casing contributes to aesthetics and organization. Printers with sleek, compact designs help keep workplaces tidy and professional. A well-structured exterior hides paper trays, cables, and mechanical parts from view, giving the entire setup a cleaner appearance.

Some modern printers even feature removable or hinged covers for easier access during maintenance. Instead of wrestling with screws or awkward panels, users can quickly reach the interior to replace cartridges, clear paper jams, or clean internal printer parts without risking damage to surrounding components.

Paper Tray (Input Tray)

Every printed page begins its journey in the paper tray. This simple yet essential part of printer holds blank sheets and feeds them into the machine with precision.

Most home printers come with a single input tray, but office models often include multiple trays for convenience. For example, one tray might hold standard A4 paper, another specialty media like envelopes, labels, or heavy cardstock. This setup saves time because users don’t have to constantly reload paper or change settings between print jobs.

Another critical aspect is paper alignment. A well-designed input tray keeps the paper straight and correctly positioned, preventing misfeeds that lead to skewed prints or frustrating paper jams. Some trays even have adjustable guides to handle different paper sizes while keeping everything centered.

In high-volume environments, high-capacity trays can store hundreds of sheets at once, reducing the need for constant reloading. This boosts productivity and ensures smooth operation for busy offices relying on multiple printer parts to work in sync.

Output Tray

Once the printing process is complete, pages emerge from the printer and land in the output tray. It might seem like a minor detail, but anyone who has printed a long document knows how quickly things can get messy without this simple part of printer.

The output tray keeps printed pages stacked neatly, preventing them from scattering on the floor or mixing out of order. Some trays come with extendable arms or side guides to handle larger print jobs, ensuring documents don’t curl or fall once the stack gets too high.

High-end printers may even feature output sorting systems, directing pages into different sections for specific users or tasks. While this isn’t standard on basic models, it shows how even seemingly simple printer parts can make a big difference in workflow efficiency.

Control Panel & Display Screen

Without the Printer control panel, operating a printer would be far more complicated. This essential part of printer acts as the command center, giving users direct access to settings, job controls, and troubleshooting information.

On older models, the control panel might consist of just a few buttons and LED indicators. Today, many printers feature full-color touchscreen displays, offering a user-friendly interface similar to a smartphone. Through the panel, you can start or cancel print jobs, adjust print quality, choose paper settings, or check ink and toner levels—all without touching a computer.

Error messages and maintenance alerts also appear here, guiding users when a particular part of printer needs attention. For example, the screen might display a paper jam location, low ink warnings, or instructions for replacing a toner cartridge.

Some advanced printers integrate wireless connectivity options directly into the panel, allowing users to print from cloud storage or mobile devices without complex setup steps. This central hub ensures smooth interaction between human operators and all the internal printer parts working behind the scenes.

Power Button & Connectivity Ports: Small Parts, Big Impact

The power button might be the smallest part of printer on this list, but it plays a crucial role. Without it, the entire machine stays dormant. A reliable power switch ensures safe startup and shutdown, protecting sensitive electronics from sudden power surges or improper shutdown sequences.

Equally important are the connectivity ports. Whether it’s a standard USB port for direct PC connections, Ethernet for office networks, or Wi-Fi modules for wireless printing, these printer parts handle all communication between the printer and external devices.

Some models even include memory card slots or direct-print USB ports, enabling users to print documents or photos without using a computer at all. With modern printers supporting multiple connection methods, these ports have become vital for seamless, flexible printing workflows.

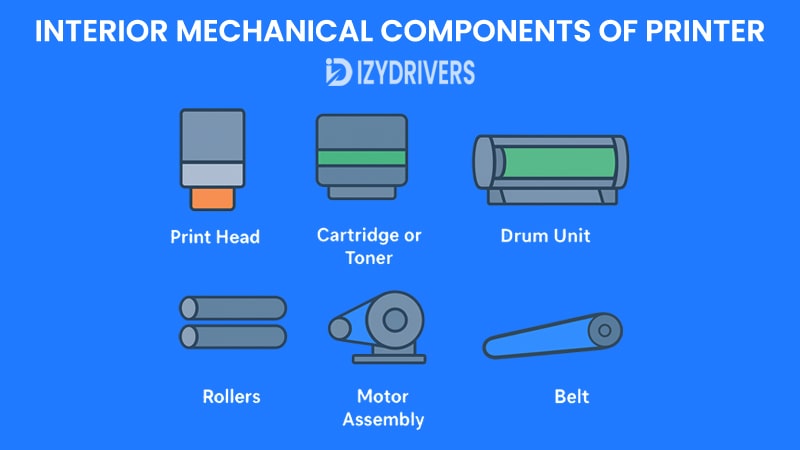

Interior Mechanical Components

While the exterior components provide protection and user control, the real action happens inside the printer. The interior mechanical parts of printer manage the entire printing process—from feeding the paper to placing ink or toner precisely where it belongs. A well-functioning interior system ensures sharp, accurate prints while reducing errors such as smudges, paper jams, or faded text.

Summary Table of Interior Printer Parts: Names and Functions

| Interior Printer Part | Main Function | Why It’s Important for Users |

|---|---|---|

| Print Head | Sprays tiny ink droplets onto paper | Determines print quality; clogs affect sharpness and accuracy |

| Cartridge / Toner | Supplies ink or toner for printing | No printing possible without it; affects color and page yield |

| Drum Unit | Transfers toner image to paper in laser printers | Ensures sharp text and clean images before fusing |

| Rollers | Moves paper smoothly through the printer | Prevents jams and misfeeds; ensures consistent paper handling |

| Belt & Motor Assembly | Coordinates motion of print head and paper feed | Maintains synchronization; prevents skewed or incomplete prints |

Let’s break down each of these essential printer parts, understand their roles, and see why proper care can make a huge difference in your printer’s performance and lifespan.

Print Head

The print head sits at the core of every inkjet printer. It contains microscopic nozzles that spray ink droplets directly onto the paper in carefully calculated patterns. These droplets are so tiny—often measured in picoliters—that they create sharp images and text even at high resolutions.

When working perfectly, the print head ensures flawless output. However, over time, ink residues or dust can block the nozzles, leading to streaks or missing lines on printed pages. This is why routine cleaning, either through built-in printer utilities or manual care, is crucial.

Some modern printers even use thermal bubble technology or piezoelectric elements to control ink flow with incredible precision. In simpler terms, these technologies push or pull ink droplets onto the page at lightning speed, ensuring crisp results for both text and images.

Neglecting print head maintenance not only affects print quality but can also shorten the life of the printer itself. So, understanding this component isn’t just for tech enthusiasts—it helps every user keep printing costs under control.

Cartridge or Toner

Without ink or toner, a printer is nothing more than a paper feeder. Inkjet printers use ink cartridges filled with liquid ink, while laser printers rely on toner cartridges containing fine powder. Both printer cartridge serve the same purpose—delivering color or black material onto paper—but in entirely different ways.

Ink cartridges are straightforward: liquid ink travels from the cartridge to the print head, then directly onto the page. They are ideal for vivid images, photos, and documents requiring high-quality color reproduction.

Toner cartridges, on the other hand, work with the drum unit and fuser assembly to fuse powder particles onto paper using heat and pressure. Laser printers are typically faster, making them popular for offices with high-volume printing needs.

Both cartridges need regular replacement, but many users now opt for refillable systems or high-capacity cartridges to reduce waste and long-term costs. Regardless of type, using genuine or high-quality cartridges prevents clogs, streaks, and potential damage to other internal printer parts.

Drum Unit

Primarily found in laser printers, the drum unit is where digital data meets physical output. Here’s how it works: a laser beam creates an electrostatic image on the drum’s surface, attracting toner particles only to the charged areas. When paper passes over the drum, these particles transfer precisely where the image or text belongs.

After this transfer, the paper moves to the fuser assembly, where heat and pressure lock the toner permanently in place. A clean drum unit ensures sharp text and consistent print density, while a dirty or worn drum often leads to faded prints or unwanted streaks.

Many users overlook drum maintenance because it seems technical, but modern printers often provide alerts when it’s time for cleaning or replacement. Ignoring these warnings can quickly turn into costly repairs or constant print quality issues.

Rollers

Among all the interior printer parts, printer rollers might be the most underappreciated. These small, rubberized wheels grab sheets from the input tray, guide them through the printing path, and deliver them neatly to the output tray.

When rollers wear out, lose grip, or collect dust, paper jams become a recurring nightmare. Printing stops mid-way, crumpled pages emerge, or the printer refuses to pick up paper at all. Regular cleaning with a lint-free cloth and replacing worn rollers can save hours of frustration.

Some high-end printers even use separate feed rollers for different paper types, ensuring smooth handling whether you’re printing on thick cardstock, envelopes, or standard office paper.

Belt & Motor Assembly

Behind the scenes, the printer belt and motor assembly synchronize the movement of both paper and the print head. Think of them as the printer’s muscles and nerves—if they lose coordination, everything falls apart.

The motor powers the mechanical motion, while belts transfer this energy to the necessary components. If the belt slips or the motor fails, you might see skewed prints, half-printed pages, or hear unusual grinding noises during operation.

Regular maintenance and timely part replacements prevent these issues, keeping the printer running smoothly for years.

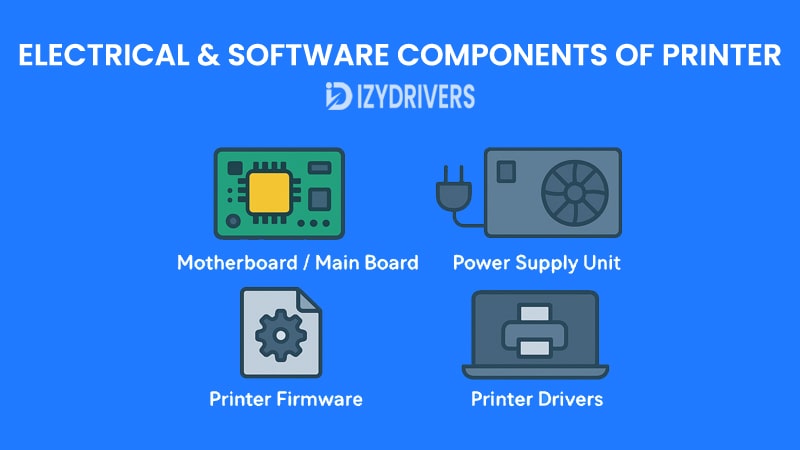

Electrical & Software Components

So far, we’ve looked at the physical parts of printer—the mechanical muscles that feed paper, apply ink, and assemble the final output. But beneath all that hardware lies the real intelligence of the machine: the electrical and software printer parts. These components interpret digital instructions from your computer, coordinate every moving part, and ensure the printer works as one seamless system.

Without these electronic and software elements, the printer would be nothing more than a box of gears and rollers. Let’s dive deeper into each key component and see how they bring the entire printing process to life.

Summary Table of Electrical & Software Printer Parts: Names and Functions

| Electrical & Software Part | Main Function | Why It’s Important for Users |

|---|---|---|

| Motherboard / Main Board | Central control hub for all printer parts | Manages signals, coordinates mechanical and software tasks |

| Power Supply Unit (PSU) | Converts wall outlet electricity to safe printer voltage | Ensures stable power, prevents component damage |

| Firmware | Internal software controlling printer operations | Updates improve performance, security, and stability |

| Printer Drivers | Translates computer commands into printer instructions | Required for accurate, error-free printing |

Motherboard / Main Board

Think of the motherboard as the printer’s central nervous system. Every signal, every print job, and every error message passes through this single control hub. Located deep inside the machine, the motherboard connects all major printer parts—from the print head and motor assembly to the display screen and connectivity ports.

When you hit “Print” on your computer, the motherboard interprets those digital instructions and decides how the mechanical parts should respond. It allocates power, coordinates timing, and ensures that data flows to the right place at the right time.

Modern motherboards in printers often include microprocessors and memory modules to handle increasingly complex tasks, such as wireless printing, duplex (two-sided) printing, and high-resolution image processing. Without this control center, even the simplest print job would fail because the machine wouldn’t know what to do first.

A failing motherboard can cause a wide range of problems—frozen displays, incomplete prints, or even a completely unresponsive printer. That’s why manufacturers build them with durable materials and protective circuits to withstand power fluctuations and heat over many years of use.

Power Supply Unit

While the motherboard serves as the brain, the power supply unit (PSU) acts as the heart, pumping energy into every printer part. It converts the high-voltage alternating current (AC) from your wall outlet into low-voltage direct current (DC) that delicate electronic circuits can safely use.

Without a properly functioning PSU, the printer won’t even power on, let alone complete a print job. Inconsistent voltage can damage sensitive components such as the motherboard, memory chips, or even the print head itself. That’s why many printers include voltage regulators and surge protection circuits to guard against electrical spikes or unstable power sources.

Some modern printers are designed with energy-saving power supplies that consume less electricity when idle, helping users reduce energy bills and environmental impact. This small yet critical part ensures every other component—from motors to software interfaces—receives stable, reliable energy.

Printer Firmware

Printer Firmware is a special kind of software stored directly inside the printer’s memory. Unlike regular computer programs, firmware controls the hardware at a very low level, telling motors when to move, heaters when to activate, and sensors when to check for paper or ink levels.

Manufacturers regularly release firmware updates to fix bugs, improve security, or add new features. For example, a firmware update might enhance wireless connectivity, improve print quality, or patch vulnerabilities that hackers could exploit in networked printers.

Ignoring firmware updates can lead to frustrating issues like slow printing, random errors, or even security risks if the printer is connected to an office network. Luckily, most modern printers allow one-click firmware updates through built-in menus or companion software on your computer.

Printer Drivers

While firmware lives inside the printer, printer drivers reside on your computer. Their job is simple but essential: translating your document or image into a language the printer understands.

Without the correct printer driver installed, the machine might produce gibberish instead of your document—or refuse to print at all. Drivers tell the printer things like:

- What page size to use

- Whether to print in color or black-and-white

- What resolution and quality settings to apply

Different operating systems (Windows, macOS, Linux) require different drivers, and manufacturers regularly release driver updates for compatibility and performance improvements.

For users, installing the correct driver often solves mysterious printing problems—such as missing pages, strange formatting, or printers showing “offline” even when connected.

Printer-Specific Parts for Different Types

Not every printer uses the same technology. While many printer parts—like rollers, trays, and power supplies—are common across all models, certain parts of printer are unique to specific types. This is because each printer technology, whether inkjet, laser, or dot matrix, handles printing tasks differently.

By understanding these specialized printer components, you can quickly identify which printer parts matter most for your needs. It also helps in troubleshooting since many problems are tied to the unique systems inside each printer type.

Inkjet Printer Parts

Inkjet printers are everywhere—from home offices to photo labs—because they deliver high-quality prints at an affordable price. But inside, these printers rely on a set of unique parts of printer designed specifically for liquid ink printing.

One critical component is the nozzle plate. This part contains hundreds of tiny nozzles that spray microscopic droplets of ink onto the paper. Keeping these nozzles clean is essential; even a small clog can cause streaks or missing lines in your printouts.

Next are the ink tanks or cartridges. Some printers have separate tanks for each color—cyan, magenta, yellow, and black—while others combine them into a single cartridge. These printer parts not only store ink but also play a role in maintaining print head pressure and preventing air bubbles from affecting print quality.

Another essential element is the print carriage. This moving assembly holds the print head and ink cartridges, gliding back and forth across the paper. If the carriage motor fails, the entire printing process comes to a halt, no matter how full your ink cartridges are.

Laser Printer Parts

Laser printers work differently. Instead of spraying liquid ink, they use a fine powder called toner and rely on static electricity and heat to fuse that powder to the paper. As a result, the printer parts inside laser machines are quite distinct from those in inkjet models.

The fuser assembly is perhaps the most important. It applies heat and pressure to permanently bond toner powder to the paper, ensuring prints don’t smudge. Without a properly working fuser, toner would simply rub off the page.

Another crucial component is the transfer belt. This part of printer carries toner images from the imaging drum onto the paper with precise alignment. Any defect here can cause blurry or shifted prints.

Finally, the corona wire (or charging roller) applies an electrical charge to the drum so it can attract toner particles in the correct pattern. A dirty or damaged corona wire often leads to print quality issues like faint or streaked images.

Dot Matrix Printer Parts

While dot matrix printers may seem outdated, they remain valuable in industries needing continuous forms or multi-layer printing, such as shipping or accounting. Their printer parts are built for durability rather than image quality.

The print head pins strike an inked ribbon against the paper, creating characters as a matrix of dots. These pins must stay aligned and wear-resistant to deliver consistent results over time.

The ribbon cartridge supplies the inked ribbon and needs regular replacement to maintain clear, dark prints. Unlike liquid ink or toner, this ribbon slowly fades as it’s used.

Finally, the tractor feed mechanism is essential for handling continuous paper with perforated edges. This part of printer keeps the paper aligned correctly, preventing jams and uneven printing across long runs.

Specialized Printer Parts for Inkjet, Laser, and Dot Matrix Models

To make it easier for you to understand, here’s a quick summary of the key parts of different printer types presented in a simple table.

| Printer Type | Unique Printer Part | Main Function | Why It Matters for Users |

|---|---|---|---|

| Inkjet Printers | Nozzle Plate | Sprays microscopic ink droplets onto paper | Clogged nozzles cause streaks or missing print lines |

| Ink Tanks / Cartridges | Stores and supplies liquid ink for printing | Affects print quality and prevents air bubble issues | |

| Print Carriage | Moves print head and cartridges across paper | Motor failure halts entire printing process | |

| Laser Printers | Fuser Assembly | Applies heat and pressure to fuse toner to paper | Prevents smudging and ensures permanent prints |

| Transfer Belt | Transfers toner image from drum to paper | Misalignment causes blurry or shifted prints | |

| Corona Wire / Charging Roller | Charges drum surface to attract toner particles | Dirt or damage leads to faint or streaked images | |

| Dot Matrix Printers | Print Head Pins | Strike inked ribbon to form characters on paper | Misaligned pins reduce print clarity and consistency |

| Ribbon Cartridge | Supplies inked ribbon for dot printing | Needs regular replacement for clear, dark prints | |

| Tractor Feed Mechanism | Feeds continuous paper with perforated edges | Prevents jams and keeps long-form printing aligned |

Conclusion

Printers may look simple from the outside, but inside, dozens of printer parts work together to deliver every page you print. From rollers that feed paper to print heads that handle ink or toner, each part of printer plays a specific role in performance and print quality.

By learning the names and functions of these components, you can troubleshoot issues more effectively, maintain your printer properly, and make smarter decisions when replacing worn-out parts. Whether it’s cleaning the nozzles, updating firmware, or choosing OEM replacements, a little knowledge goes a long way in keeping your printer running smoothly.

Understanding printer parts isn’t just for technicians—it helps anyone who wants to avoid downtime, save money on repairs, and get the most out of their printer investment.

FAQs About Printer Parts

What are the most important parts of a printer to maintain regularly?

The print head, ink or toner cartridges, rollers, and fuser assembly are the main printer parts that require regular maintenance to prevent common issues like paper jams or faded prints.

How often should I clean the internal parts of printer machines?

For home use, cleaning every three to six months is usually enough. In office environments with heavy printing, monthly cleaning of key printer parts like rollers and nozzles is recommended.

Are aftermarket printer parts as good as OEM parts?

Some high-quality aftermarket printer parts perform well, especially from reputable brands. However, OEM parts usually offer the best compatibility, durability, and warranty support.

Why does my printer keep showing error codes even after replacing parts?

Many error codes are related to firmware or software issues rather than mechanical parts of printer. Updating drivers or resetting the printer can often solve these problems.

How can I extend the lifespan of my printer parts?

Regular cleaning, using quality paper, replacing cartridges before they’re empty, and updating firmware all help extend the life of key printer parts and prevent costly repairs.