Printers often look simple on the outside—just a box with a paper tray, a lid, and maybe a few buttons. But inside, they’re surprisingly complex machines made of dozens of small parts working together in perfect harmony. Every line of text, every detailed graphic, and every smooth gradient relies on a hidden network of printer belt, rollers, gears, and motors.

Among of printer parts, there’s one that many users rarely hear about, yet it plays a crucial role in making sure your prints look sharp and consistent: the printer belt. Unlike ink cartridges or paper trays that need your attention regularly, the printer belt is quietly working in the background. You don’t really notice it—until something goes wrong.

Imagine this scenario: you hit “print” for an important document, but the output is skewed, lines appear wavy, or the machine makes an unpleasant grinding noise. At first glance, you might think it’s the ink or the paper causing trouble. But often, the real culprit is a worn-out or misaligned printer belt. This small strip of reinforced rubber or plastic can decide whether your printer works like a precision instrument or becomes a source of endless frustration.

What makes the printer belt fascinating is that it exists in almost every type of printer—inkjet, laser, even high-end industrial models. Its function may differ slightly depending on the machine, but the principle remains the same: it ensures precise, smooth movement, whether it’s guiding the printhead across the page or transferring toner to paper. Without it, even the most advanced printer would struggle to do its job.

This article takes you behind the scenes of this often-overlooked component. You’ll learn what a printer belt actually is, where it sits inside your device, and how it silently contributes to print quality. We’ll explore the common problems that affect printer belts, the telltale signs you should watch out for, and most importantly, how to fix or replace a faulty belt without wasting money.

Along the way, you’ll also discover practical maintenance tips to extend the life of your printer belt, guidance on choosing between OEM and compatible replacements, and answers to frequently asked questions from everyday users. Whether you’re a casual home user, a small business owner, or someone who manages multiple printers in an office setting, understanding the printer belt can save you time, money, and a lot of unnecessary stress.

So, the next time your printer starts acting up, you won’t just blame the ink or paper—you’ll know to look deeper. And that knowledge alone puts you ahead of most users.

What Is a Printer Belt?

A printer belt is one of those hidden components that most users never think about—until the moment it fails. In simple terms, it’s a flexible, reinforced strip made of rubber, synthetic plastic, or a composite material that ensures smooth and precise motion inside your printer. Unlike ink cartridges or paper trays that you interact with daily, the belt quietly performs its job in the background, making sure everything runs in sync.

The exact role of the belt depends on the type of printer. In inkjet printers, it’s responsible for moving the printhead carriage back and forth across the page, laying down ink with microscopic accuracy. In laser printers, the belt takes on a different role, acting as a transfer mechanism that carries toner particles from the cartridges to the paper. Both tasks may sound simple, but without the belt, the printing process would collapse.

Think of it this way: if a printer were a stage play, the cartridges and paper are the actors, while the printer belt is the stage crew. You don’t always notice it, but without the crew, the performance falls apart. A broken or misaligned belt can cause crooked text, blurry graphics, or even a complete system error.

Because it’s not visible from the outside, many users underestimate its importance. Yet, it is the backbone of precision in printing. Whether you’re dealing with a budget-friendly home printer or a heavy-duty office machine, the belt is a key factor in producing crisp, professional-quality output. Understanding what it is—and how it works—is the first step to maintaining your printer’s performance.

Where It Is Located Inside a Printer

Finding the printer belt isn’t always obvious, since it’s hidden inside the machine’s body. But once you know where to look, identifying its position becomes much easier. The location depends mainly on the type of printer you are using.

Inkjet Printer Belt Location

In an inkjet printer, the belt is stretched horizontally across the interior of the device. It is directly connected to the printhead carriage—the small component that moves left and right as it sprays ink onto the paper.

Each time you print, the belt pulls the carriage with precise, controlled motion. If the belt slips or loosens, the carriage will wobble, leading to crooked lines or misaligned text.

Laser Printer Belt Location

Laser printers use a different belt system known as the transfer belt. Instead of moving a carriage, this belt sits beneath the toner cartridges, between them and the paper path. Its main role is to collect toner particles from each cartridge and place them onto the sheet before the fuser unit locks the image permanently.

In color laser printers, this is particularly important because the transfer belt aligns multiple layers of toner—cyan, magenta, yellow, and black—so they form a perfect image.

Understanding the belt’s position helps when diagnosing problems. Strange noises, skewed prints, or streaks often trace back to issues in these exact areas.

For users willing to open the casing carefully, recognizing the belt’s placement is the first step in checking whether it’s loose, worn out, or contaminated with dust. Knowing its location means you’re no longer guessing—you’re targeting the heart of the issue.

Types of Printer Belts

Not all printer belts serve the same purpose. The two most common varieties are the carriage belt found in inkjet printers and the transfer belt used in laser printers. Each has a unique role but is equally important in delivering high-quality prints.

Carriage Belt in Inkjet Printers

The carriage belt is a long, toothed strip that controls the back-and-forth motion of the printhead. Without it, the printhead wouldn’t move smoothly, and ink would be sprayed unevenly across the paper. A healthy carriage belt ensures every character and image appears sharp and aligned.

When it wears out, you may notice jagged text, lines that don’t match up, or loud grinding sounds as the carriage struggles to move.

Transfer Belt in Laser Printers

In laser printers, the belt works more like a conveyor system. The transfer belt collects toner from the cartridges and layers it onto the sheet in exact alignment.

This is especially crucial for color printers, where four different toner colors must blend perfectly to create a crisp image. If the transfer belt is damaged or dirty, colors can appear faded, shifted, or completely misaligned.

Key Differences Between the Two

The carriage belt is all about movement control—it makes sure the printhead glides with precision. The transfer belt is about image transfer—it guarantees toner is deposited onto paper in the right position.

Both types may look like simple strips at first glance, but each serves as the backbone of the printing process in its respective machine.

Carriage Belt vs Transfer Belt: Key Differences and Features

| Feature | Carriage Belt (Inkjet) | Transfer Belt (Laser) |

|---|---|---|

| Function | Moves printhead | Transfers toner to paper |

| Location | Printhead carriage | Between toner cartridges & paper feed |

| Common Issues | Misalignment, worn teeth | Color misalignment, scratches |

| Typical Lifespan | 5–7 years | 50,000–100,000 pages |

Functions of a Printer Belt

Role in Inkjet Printers

In inkjet printers, the printer belt—commonly referred to as the carriage belt—has one of the most essential tasks: moving the printhead carriage smoothly across the page. Every time you send a document to print, the belt pulls the carriage from left to right (and back again) while maintaining perfect alignment with the paper feed. This ensures that ink droplets land exactly where they should, creating sharp text and clean graphics.

Without a properly functioning belt, the printhead would jerk, misalign, or even stop mid-way, leading to distorted or incomplete prints. For instance, you might see lines that don’t connect properly, blurry edges, or text that drifts diagonally across the page. These issues aren’t usually caused by the ink itself, but by a carriage belt that has loosened, slipped, or worn out.

Another key function of the carriage belt is maintaining synchronization with other moving parts. Printers operate like choreographed machines—rollers feed the paper while the carriage deposits ink. The belt ensures both actions are perfectly timed. If the belt lags, even by a fraction of a second, you’ll see visible errors on the page. In short, the belt doesn’t just move parts; it keeps the entire printing process coordinated.

Role in Laser Printers

Laser printers use a different type of belt—the transfer belt—and its role is just as vital. Instead of moving a printhead, this belt acts as a middleman between toner cartridges and paper. Each toner color (cyan, magenta, yellow, and black) is layered onto the belt in the correct order before being transferred to the sheet. Think of it as a painter’s palette, where colors are blended and aligned before they touch the canvas.

This precise layering is what allows laser printers to produce sharp, full-color documents at high speed. Without a properly functioning transfer belt, you might see color shifts, faded sections, or prints where the layers don’t align. A small misstep in the belt’s movement can lead to text that looks shadowed or graphics that appear blurry.

Another function of the transfer belt is to maintain even distribution of toner. Toner particles are extremely fine, and without consistent movement, they can clump together or scatter unevenly. The belt ensures they are spread in a uniform layer, so the final print looks professional. In short, the transfer belt is the quiet hero of color laser printing, guaranteeing that every page comes out crisp and vibrant.

Contribution to Print Quality and Speed

Whether in inkjet or laser printers, the belt has one universal responsibility: delivering precision and efficiency. It acts as the stabilizer that allows a printer to work quickly without sacrificing quality. By guiding motion with controlled accuracy, the belt makes sure every drop of ink or particle of toner lands in the right place—no smudges, no misalignments, no wasted effort.

For high-speed office printers, the belt is especially important. Businesses rely on printers that can handle hundreds of pages per hour without breaking down. A worn or poorly aligned belt slows everything down, causing jams, reprints, and costly downtime. On the other hand, a well-maintained belt allows a machine to run at full capacity, delivering sharp prints consistently.

It’s also worth noting that print quality isn’t just about clarity—it’s about consistency. A belt that operates smoothly ensures that page one looks exactly the same as page 100, even in large print jobs. This consistency is critical for professional settings, where brand colors, logos, and fine details must be reproduced with accuracy.

Ultimately, the function of a printer belt goes beyond simple motion. It embodies the balance between speed and precision—the two factors that define printing performance. Without it, even the most advanced printer would fail to deliver reliable results.

Signs of a Faulty Printer Belt

Common Symptoms You Should Notice

A faulty printer belt rarely fails suddenly—it usually gives warning signs. One of the most common symptoms is misaligned prints. You might see text that looks slightly shifted to one side, or images that appear stretched or broken into uneven lines. These distortions often make people think their printer needs new ink or calibration, but in reality, the belt could be the hidden culprit.

Another frequent symptom is grinding or squeaking noises when printing. Since the belt is responsible for guiding mechanical motion, a loose or damaged belt can rub against gears or slip during movement, producing unusual sounds. Ignoring these noises can eventually lead to complete belt failure.

Paper jams are also a telltale sign, especially when they happen repeatedly without obvious cause. A damaged belt may lose tension, forcing the printer’s moving parts out of sync with the paper feed. In turn, sheets get stuck, pulled incorrectly, or exit with uneven ink coverage.

Lastly, watch out for inconsistent print speed. A printer that pauses, stutters, or slows down mid-job often indicates that the belt is struggling to maintain proper motion. While these symptoms might appear minor at first, they quickly escalate into bigger issues if left unchecked.

How to Tell Belt Problems Apart from Other Issues

One of the biggest challenges in printer troubleshooting is figuring out whether the belt is really to blame. After all, symptoms like streaks, faded colors, or skewed lines can also result from clogged nozzles, dirty rollers, or low-quality paper. So how can you tell if the problem lies with the belt?

A good indicator is when multiple issues occur simultaneously. For example, if you hear grinding noises and notice misaligned prints at the same time, the belt is a strong suspect. Another giveaway is when cleaning the cartridges or rollers doesn’t solve the problem. If the printer continues to misbehave despite fresh ink or toner, it’s worth checking the belt.

You can also perform a simple diagnostic test. Many printers allow you to print a built-in alignment or test page. If the lines appear uneven or shifted in a repeating pattern, that often points to a mechanical issue like the belt rather than a one-time paper feed error. Unlike rollers or cartridges, the belt affects the movement system, so problems usually show up as repeating, consistent flaws across multiple pages.

By learning to distinguish belt-related symptoms from other issues, you save both time and money. Instead of replacing cartridges unnecessarily, you can focus directly on the real cause of the problem.

Diagnosing Printer Belt Issues Safely

Once you suspect the belt is at fault, the next step is diagnosis. However, safety should always come first. Printers may look harmless, but they contain delicate parts and, in the case of laser printers, high-voltage components. Always unplug the printer before opening it, and refer to the manufacturer’s guide when possible.

For inkjet printers, carefully remove the top casing to locate the carriage belt. Inspect it for signs of wear, such as cracks, fraying, or slackness. If the belt appears loose, try moving the printhead carriage gently—excessive wobbling usually confirms that the belt has lost tension.

In laser printers, accessing the transfer belt often requires opening a panel behind or beneath the toner cartridges. Look for scratches, toner buildup, or uneven wear along the belt’s surface. A healthy transfer belt should look smooth, without streaks or dents.

It’s important not to apply oil or force during inspection, as this can damage the belt or surrounding components. If you’re not confident handling the belt directly, it’s best to rely on a service professional. Still, knowing how to check it gives you valuable insight into whether your printer’s issues are belt-related or caused by something else entirely.

Common Printer Belt Problems

Wear and Tear

Like any mechanical part, printer belts are subject to wear and tear over time. Constant movement, friction, and exposure to dust or debris gradually degrade the material. For inkjet printers, the carriage belt’s teeth may wear down, causing the printhead to lose proper alignment. In laser printers, the transfer belt surface can become scratched or worn, leading to uneven toner transfer.

Wear and tear often starts subtly. You may notice occasional misalignment, slight streaks, or minor noise. However, ignoring these early signs allows small problems to escalate into major issues. Regular inspection can catch wear before it impacts print quality or causes complete failure. Replacing a worn belt promptly ensures consistent output and avoids additional stress on other mechanical components.

Slipping or Loose Belt

A belt that slips or becomes loose is another common problem. This often happens when the tension mechanism weakens or the belt stretches beyond its intended length. In inkjet printers, a loose carriage belt leads to inaccurate printhead movement, resulting in jagged lines, blurred text, or uneven graphics. In laser printers, a slipping transfer belt may misalign colors or produce ghosted images.

Slipping belts can be caused by improper installation, accidental tugging, or even normal stretching over time. The good news is that some cases can be corrected by re-tensioning the belt, while more severe cases require a replacement. Recognizing the signs early—misaligned prints, repeated errors, or abnormal noises—can save money and prevent damage to other printer parts.

Broken Teeth or Cracks

Belts with broken teeth or cracks are particularly damaging. The teeth on a carriage belt engage with gears to move the printhead precisely. If even a few teeth break, the printhead may skip steps, producing repeated gaps, wavy lines, or misaligned text. In laser printers, cracks or tears in the transfer belt can disrupt toner transfer, leaving blank streaks or faded sections on the page.

Broken teeth or cracks typically occur due to prolonged use, high heat, or mechanical stress. Once damage reaches this stage, repair is usually not an option—replacement is necessary. Ignoring this problem can cause further damage to rollers, motors, or cartridges, increasing repair costs significantly.

Contamination by Dust or Ink

Even minor contamination can compromise a printer belt’s performance. Dust, toner particles, or ink residue may accumulate on the belt over time. In inkjet printers, sticky ink deposits can make the carriage belt resist smooth movement, creating uneven prints or noisy operation. In laser printers, dust or toner on the transfer belt can lead to streaks, spots, or color inconsistencies.

Cleaning the belt carefully with a soft, lint-free cloth or recommended cleaning solution can prevent these issues. Avoid harsh chemicals or excessive moisture, as these can further damage the belt. Routine maintenance—keeping the printer interior clean and free from debris—extends belt life and ensures consistently high print quality.

How to Fix or Replace a Printer Belt

Tools You May Need

Before attempting any repair or replacement, it’s important to gather the right tools. For most inkjet printers, you’ll need a small screwdriver set, a pair of tweezers, and possibly a replacement belt recommended by the manufacturer. For laser printers, additional items like gloves to prevent toner stains, a soft lint-free cloth, and sometimes a plastic prying tool are useful.

Having the correct tools ensures you don’t damage sensitive components. Avoid using excessive force or improvised instruments like knives or metal picks, as these can scratch or crack the printer housing. Preparation is key: set up a clean, well-lit workspace and keep the printer unplugged to prevent accidental movement of internal parts or electrical hazards.

Step-by-Step Replacement Guide

Replacing a printer belt varies slightly between inkjet and laser models, but the general steps are similar:

- Power down and unplug the printer.

- Open the printer casing carefully to expose the belt and associated components.

- Remove the old belt by loosening tension mechanisms or screws. Take note of its orientation and path for correct installation of the new belt.

- Install the replacement belt, ensuring proper alignment with gears and pulleys. Check that tension is even and teeth are properly engaged (for carriage belts).

- Close the casing and plug in the printer.

- Run a test page to verify alignment and smooth operation.

Following these steps carefully can prevent common mistakes such as a loose belt, incorrect alignment, or jams during initial operation.

When to Repair vs. When to Replace

Not every belt problem requires a full replacement. Minor slipping or misalignment may sometimes be corrected by re-tensioning or cleaning the belt. Small deposits of dust or toner can often be removed safely, restoring function without new parts.

However, belts that are worn, cracked, or have broken teeth should be replaced immediately. Attempting to repair severe damage usually results in continued printing issues and may even damage other components. A rule of thumb: if you see visible wear or repeated performance problems after cleaning or adjustment, replacement is the safest option.

Professional Service vs. DIY

While DIY repair is possible for many home printers, professional service is recommended in some cases. Laser printers, especially large color models, often have transfer belts located deep inside the machine, sometimes requiring specialized tools and handling to avoid damage.

Professional technicians can also provide genuine replacement parts, proper calibration, and warranty coverage. On the other hand, DIY repair offers cost savings and convenience, especially for common inkjet models. Understanding your printer type, the extent of the belt issue, and your comfort level with mechanical repairs will help you decide between DIY and professional service.

Preventive Maintenance for Printer Belts

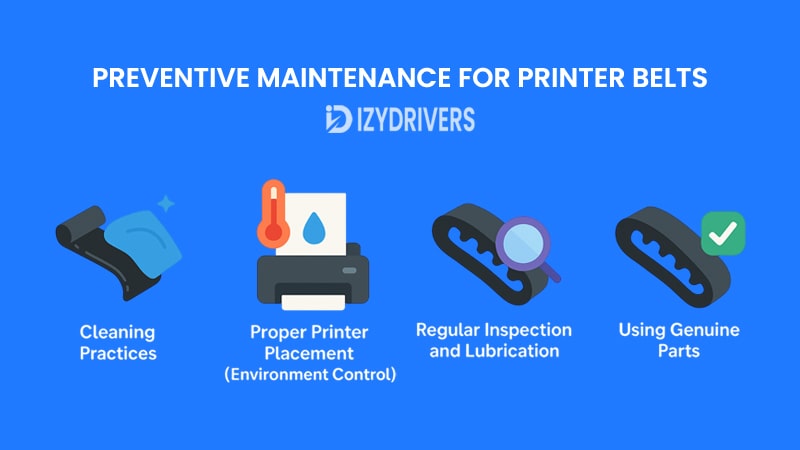

Cleaning Practices

Regular cleaning is one of the simplest ways to extend the life of a printer belt. Dust, toner particles, and ink residue can accumulate over time, causing the belt to slip, stick, or wear unevenly. For inkjet printers, a soft, lint-free cloth slightly dampened with water or a manufacturer-recommended cleaning solution works well. Gently wipe along the belt and the surrounding areas without applying excessive pressure.

For laser printers, it’s important to remove any loose toner particles using a soft cloth or a specialized toner vacuum. Avoid using regular vacuums or compressed air, as these can scatter toner inside the printer or damage delicate components. Performing cleaning every few months, or sooner in dusty environments, helps prevent common problems like streaks, misalignment, or noisy operation.

Proper Printer Placement (Environment Control)

Environmental factors significantly impact printer belt longevity. Placing a printer in a clean, dust-free area reduces the chance of debris interfering with the belt. Avoid locations near windows, open vents, or areas with high humidity, as excessive moisture can cause belts to stretch or degrade faster.

Temperature control is also crucial. Extreme heat can weaken the material, especially in plastic or composite belts, while extremely cold environments may make the belt brittle. A stable, moderate room temperature not only protects the belt but also improves overall printer performance and prevents paper jams caused by warped sheets.

Regular Inspection and Lubrication

Routine inspections allow you to catch small issues before they become major problems. Every few months, carefully open the printer casing and check the belt for signs of wear, slackness, or minor damage. Look for cracks, fraying, or dust accumulation.

Lubrication can also help maintain smooth movement, but it must be done carefully. Only use manufacturer-approved lubricants and avoid over-application, as excess oil can attract dust or contaminate rollers. In most home printers, lubrication is rarely needed, but for high-use office models, periodic light lubrication keeps the belt moving freely and prevents unnecessary strain on the motor and gears.

Using Genuine Parts

When it comes to replacement belts or related components, always use genuine or recommended parts whenever possible. OEM (Original Equipment Manufacturer) belts are designed specifically for your printer model, ensuring proper fit, tension, and material durability. Using low-quality or generic alternatives can lead to premature wear, misalignment, or even damage to surrounding components.

Investing in genuine parts not only prolongs belt life but also maintains print quality and avoids unexpected repair costs. Coupled with cleaning, inspection, and proper placement, choosing the right parts forms a complete preventive maintenance routine that keeps your printer running smoothly for years.

Choosing the Right Printer Belt Replacement

OEM vs. Compatible Parts

When replacing a printer belt, you have two main options: OEM (Original Equipment Manufacturer) parts or compatible aftermarket belts. OEM belts are made by the printer manufacturer and are guaranteed to fit your specific model perfectly. They maintain proper tension, alignment, and durability, which helps preserve print quality and reduces the risk of damaging other components.

Compatible belts, on the other hand, are third-party replacements that may be cheaper but vary in quality. Some work just as well as OEM parts, while others may stretch more quickly, wear unevenly, or cause alignment issues. Choosing the right belt depends on your budget, printer usage, and willingness to take risks. For high-volume or professional printing environments, OEM is usually the safest choice. For occasional home use, a high-quality compatible belt can be a reasonable alternative.

Cost Considerations

The cost of replacement belts varies widely depending on the type and brand of printer. Inkjet carriage belts are typically less expensive, often ranging from $10 to $50, while laser transfer belts, especially for color printers, can cost $50 to $200 or more. OEM parts are usually at the higher end of the range, while compatible alternatives may be 30–50% cheaper.

While the initial cost is a factor, it’s important to consider long-term value. A cheaper, low-quality belt might save money upfront but could lead to repeated failures, misaligned prints, or even damage to other printer components, resulting in higher overall costs. Investing in a quality replacement often pays off through better performance, longer lifespan, and fewer repair headaches.

Where to Buy Quality Printer Belts

Finding a reliable source for printer belts is crucial. Authorized dealers or manufacturer websites are the most dependable options for OEM parts, ensuring compatibility and warranty coverage. For compatible belts, reputable online retailers or specialized printer supply stores are safer than generic marketplaces where quality is uncertain.

Before purchasing, double-check your printer model, belt type (carriage vs. transfer), and part number. Reading reviews and verifying seller credibility can prevent mistakes, such as buying the wrong belt size or low-quality materials. Additionally, some suppliers offer installation guides or customer support, which can be invaluable if you are replacing the belt yourself.

By carefully choosing the right replacement, you not only restore your printer’s performance but also extend its overall lifespan, maintain print quality, and avoid recurring problems that could have been prevented with a simple, informed purchase.

Printer Belt vs. Other Printer Components

Difference from Printer Roller

While the printer belt moves the printhead or transfers toner, the printer roller is responsible for feeding paper through the machine. Rollers grip and advance the paper sheet, ensuring it aligns correctly with the printhead or transfer belt.

A common confusion is thinking that paper jams or misaligned prints are always due to the rollers. While rollers can cause such issues, the belt plays a different role: it controls the precision of movement. Even if the rollers feed paper perfectly, a worn or misaligned belt can still produce skewed lines or blurry graphics. Understanding this distinction helps diagnose problems more accurately.

Difference from Printer Drum

The printer drum is another essential component, especially in laser printers. It’s a cylindrical surface that receives toner and then transfers it to paper via the transfer belt. Unlike the belt, which moves or guides parts, the drum’s main function is toner adhesion and image formation.

A damaged drum often causes streaks, blank areas, or faded prints, but these issues differ from those caused by a faulty belt. Belt problems typically manifest as misaligned prints, uneven motion, or repeated patterns of error. Knowing the difference between drum and belt issues allows users to target repairs effectively, preventing unnecessary replacement of multiple components.

Difference from Carriage Motor

In inkjet printers, the carriage motor drives the movement of the printhead along the belt. While the motor provides power, the belt ensures that this motion is smooth and precise. A motor failure can stop movement entirely, whereas a belt issue causes inconsistent or jagged movement.

In other words, the motor and belt work together: the motor supplies energy, the belt guides it accurately. This relationship highlights why both components are critical. Diagnosing belt issues independently of motor problems requires careful observation of print patterns, noise, and smoothness of carriage motion. Recognizing these differences can save time, prevent unnecessary repairs, and maintain consistent print quality.

Printer Belt vs Other Components: Function and Print Quality Impact

| Component | Function | Effect on Print Quality |

|---|---|---|

| Printer Belt | Guides movement or transfers toner | Misalignment, streaks, blurry prints |

| Roller | Feeds paper | Paper jams, misfeeds |

| Drum | Holds & transfers toner (laser) | Faded prints, streaks |

| Carriage Motor | Powers printhead movement | Printer stops or jerky motion |

Conclusion

The printer belt may be a small, often overlooked component, but it is critical to producing precise, smooth, and consistent prints. From guiding the inkjet printhead to transferring toner in laser printers, the belt’s role directly impacts print quality, speed, and reliability.

Understanding the types, functions, and common problems of printer belts empowers users to diagnose issues effectively, perform preventive maintenance, and make informed choices when replacement is necessary. Regular cleaning, proper environmental placement, and choosing high-quality replacement parts can extend the belt’s lifespan and keep your printer performing at its best.

Whether you are a casual home user, a small business owner, or manage multiple printers in an office, knowing your printer belt inside out saves time, money, and frustration. By treating this hidden part with care, you ensure that every document, report, or project comes out crisp, professional, and perfectly aligned—page after page.

FAQs About Printer Belts

How long does a printer belt usually last?

The lifespan of a printer belt depends on the type of printer and usage frequency. For inkjet carriage belts, it can last 5–7 years under moderate use. Transfer belts in laser printers, especially color models, typically last 50,000–100,000 pages. Regular maintenance and clean environments can extend this lifespan, while heavy-duty printing or dusty conditions may shorten it.

Can I lubricate a printer belt?

Lubrication is rarely needed for most home printers. Only high-use office printers may benefit from light lubrication. Use manufacturer-approved lubricants and apply sparingly. Over-lubrication or incorrect oils can attract dust, cause slipping, or damage nearby components. Always check the printer manual before attempting lubrication.

What happens if I keep using a broken belt?

Continuing to print with a damaged belt can worsen misalignment, produce blurry or incomplete prints, and even cause damage to other printer components, like the motor or rollers. It may also lead to repeated paper jams and increase repair costs. Immediate replacement or professional servicing is recommended.

Are all printer belts universal?

No. Printer belts are model-specific. Carriage belts differ between inkjet brands and models, while transfer belts vary for laser printers. Using the wrong belt can cause misalignment, damage, or even total printer failure. Always check part numbers or consult the manufacturer when replacing belts.

How much does a replacement usually cost?

Replacement costs vary. Carriage belts for inkjet printers are generally $10–$50, while laser transfer belts, especially in color printers, can cost $50–$200. OEM belts tend to be more expensive but offer guaranteed fit and durability, while high-quality compatible belts can be a cost-effective alternative.