Back in the early days of personal computing, when chunky monitors ruled the desks and floppy disks carried mere kilobytes of data, printing technology was equally rugged and mechanical. Among the earliest and most enduring types of printers was the Dot Matrix Printer, a device that relied on a precise dance of pins, ribbons, and impact strikes to put text on paper.

Even though technology has moved on to sleek inkjets and blazing-fast laser printers, dot matrix printers have carved a niche for themselves in certain industries. Their ability to print on multi-part forms, withstand dusty environments, and operate with low maintenance costs keeps them relevant even in 2025.

Whether you’re curious about printing history, searching for an affordable solution for continuous paper printing, or dealing with legacy systems in your business, this article will provide a complete roadmap for understanding dot matrix printers inside out.

What is a Dot Matrix Printer?

A Dot Matrix Printer is a type of impact printer that creates characters and images by striking an ink-soaked ribbon against paper, much like a typewriter. The key difference lies in its use of a grid of tiny pins—called a print head—that form dots on the paper to create letters, numbers, and symbols. These dots combine to produce text or simple graphics.

Unlike inkjet or laser printers that use advanced, non-impact printer technologies, dot matrix printers rely on mechanical impact to transfer ink. This makes them especially useful in environments where multiple copies (like carbon forms) or continuous paper rolls are needed.

Key Characteristics of Dot Matrix Printers

- Impact Printing Technology: Works by physically striking the ribbon and paper.

- Dot-Based Printing: Characters are formed by a matrix of dots instead of continuous lines.

- Monochrome Printing: Most models print in black, though some support limited color ribbons.

- Durable and Cost-Effective: Known for long service life and low operational costs.

Because of their durability and unique capabilities, this printers have remained in use for decades, especially in industrial environments, financial institutions, and logistics companies where reliability often matters more than print aesthetics.

How a Dot Matrix Printer Works

The dot matrix printing process combines mechanical precision with electronic control, making it unique among traditional printing methods. Instead of spraying or fusing ink, a dot matrix printer uses a print head with tiny pins that physically strike an ink ribbon, transferring ink onto the paper in the form of small dots. These dots collectively form characters, symbols, or even basic graphics.

Here’s how it all happens:

The Role of the Print Head and Ribbon

At the center of the process is the print head, a small component containing multiple electromagnetically driven pins arranged vertically. Depending on the printer model:

- 9-pin printers deliver draft-quality text at high speed.

- 24-pin printers produce near-letter quality with smoother characters.

As the printing begins:

- The print head moves horizontally across the page.

- Pins are activated to strike the ink-soaked ribbon against the paper.

- Each strike forms a tiny dot, and collectively, these dots create the desired text or graphics.

Impact Printing Technology Explained

Because the pins physically strike the ribbon and paper, dot matrix printers are classified as impact printers.

- This process is mechanical, similar to a typewriter but more precise because it uses dots instead of full characters.

- The platen roller keeps the paper stable while the feed mechanism advances it line by line after each pass.

Understanding Characters and Dot Formation

Each character is made up of a matrix of dots, such as 5×7 or 9×9 patterns. Higher pin counts allow for:

- Denser dot patterns for sharper text

- Simple graphics such as logos, barcodes, or forms

Step-by-Step Process of How a Dot Matrix Printer Works

| Step | Action | Components Involved | Mechanical Details | Output / Notes |

|---|---|---|---|---|

| 1 | Receive print job | Host computer, printer interface, controller | Data is sent to the printer; the controller translates text/images into dot patterns. | Print buffer is prepared. |

| 2 | Define pin firing pattern | Controller, print-head driver, motor | Controller maps each character into a dot matrix and sends signals to the print-head pins. | Pin patterns and head position are set. |

| 3 | Start print head movement | Print head assembly, stepper motor | Print head moves horizontally across the paper while timing signals coordinate pin firing. | Smooth, controlled head movement. |

| 4 | Pins strike ribbon → dot formation | Pins, ribbon, platen roller | Electromagnetic pulses trigger pins to strike the ribbon, transferring ink dots to the paper. | Single dot appears on paper. |

| 5 | Repeat firing as head moves | Pins, controller, head mechanism | Pins fire repeatedly along the line to form characters and graphics. | Complete line of text is formed. |

| 6 | Advance paper | Platen roller, feed mechanism, stepper motor | Paper advances vertically after each line to prepare for the next. | Next line ready for printing. |

| 7 | Multi-part form printing (if needed) | Pins, carbon forms | Impact is strong enough to print through carbon or multi-part forms. | Multiple copies printed at once. |

| 8 | Repeat until job completes | All components | Steps 3–6 repeat until the entire job finishes. | Document fully printed. |

| 9 | Job completion & reset | Print head, ribbon advance, sensors | Print head returns to home position, ribbon advances for next use. | Printer ready for next job. |

Components of a Dot Matrix Printer

A Dot Matrix Printer is made up of several mechanical and electronic components that work together to deliver accurate, durable, and low-cost printing. Understanding each part helps in maintenance, troubleshooting, and optimizing performance.

Here’s a detailed look at the main components:

Print Head

The print head is the core component of a dot matrix printer. It contains:

- Pins arranged vertically (e.g., 9 or 24 pins) to create dot patterns.

- Electromagnetic coils that drive each pin to strike the ribbon and paper.

Function:

- Converts electronic signals into physical impact printing.

- Determines the print quality and speed—more pins usually mean better resolution.

Ribbon

The ribbon is an ink-coated fabric strip positioned between the print head and the paper.

- Comes in a cartridge or spool format depending on the printer model.

- Continuous loop design ensures long-term use before replacement.

Function:

- Transfers ink to paper when struck by pins.

- Can be single-color (usually black) or multi-color for basic color printing.

Platen Roller

The platen roller printer is a cylindrical rubber roller located behind the paper.

- Provides firm backing so that pins can strike effectively.

- Ensures consistent pressure for clear printing results.

Function:

- Keeps the paper stable and properly aligned.

- Advances the paper vertically after each line is printed.

Tractor Feed Mechanism

The tractor feed mechanism is responsible for moving continuous paper accurately through the printer.

- Uses sprockets and perforated edges on the paper to maintain alignment.

- Essential for multi-part forms or long printing tasks.

Function:

- Ensures paper moves smoothly and evenly without slippage.

- Critical for businesses using invoices, receipts, or log sheets.

Control Panel & Motherboard

The control panel provides basic printer status indicators such as:

- Power On/Off

- Paper Feed

- Error Notifications

Meanwhile, the motherboard houses the printer’s logic circuits and microcontrollers:

- Processes input from the computer.

- Coordinates motor movements, pin firing, and paper feeding.

Other Supporting Components

- Stepper Motors: Control precise movement of the print head and paper feed.

- Sensors: Detect paper presence, print head position, and ribbon end-of-life.

- Power Supply Unit (PSU): Delivers power to all electronic and mechanical printers parts.

2 Types of Dot Matrix Printers

Dot matrix printers are generally classified based on how they print characters and the number of pins in the print head. Understanding these types is essential for choosing the right printer for a specific application.

Below are the two main types:

1. Serial Dot Matrix Printer (SDM)

The Serial Dot Matrix Printer is the most common type. It prints characters one at a time as the print head moves horizontally across the page.

Characteristics:

- Prints one character or a few dots at each step.

- Typically comes in 9-pin and 24-pin versions:

- 9-pin printers: Faster, but lower print quality (ideal for receipts or invoices).

- 24-pin printers: Higher quality output, suitable for detailed text or simple graphics.

Advantages:

- Compact design.

- Widely available and cost-effective.

- Flexible for both single-sheet and continuous paper.

Use Cases:

- Retail billing systems

- Bank transaction records

- Office receipts

2. Line Dot Matrix Printer (LDM)

The Line Dot Matrix Printer prints an entire line of text at once rather than character by character. It uses a long print head that spans the full width of the paper.

Characteristics:

- Much faster than serial printers.

- Often used in high-volume printing environments.

- Still uses impact technology but covers more surface area per pass.

Advantages:

- Higher printing speed (lines per second vs characters per second).

- Suitable for large data printouts like logs or reports.

Use Cases:

- Industrial settings

- Large-scale data processing centers

- Utility bill printing

Comparison Types of Dot Matrix Printers

| Feature | Serial Dot Matrix Printer (SDM) | Line Dot Matrix Printer (LDM) |

|---|---|---|

| Printing Method | Character-by-character | Line-by-line |

| Speed | Moderate (50–600 cps) | High (up to several hundred lps) |

| Print Head | Small, moves horizontally | Wide, spans entire page width |

| Typical Use | Receipts, invoices, office printing | Industrial, data centers, billing |

| Print Quality | 9-pin = draft, 24-pin = near-letter | Comparable to 24-pin SDM printers |

| Cost | Lower | Higher |

Key Features of Dot Matrix Printers

Despite being one of the oldest printing technologies, Dot Matrix Printers (DMPs) remain relevant in specific industries because of their unique features. These features set them apart from inkjet and laser printers, making them indispensable in environments where durability, cost-efficiency, and multi-part printing are priorities.

Below are the most important features:

Printing Speed

Dot matrix printers measure speed in Characters Per Second (CPS) or Lines Per Second (LPS) depending on the model.

- 9-pin printers: Typically range from 50 to 400 CPS.

- 24-pin printers: Offer lower speed but higher print quality.

- Line printers: Can reach several hundred LPS, suitable for massive data printing.

Printing speed affects productivity in offices, banks, and warehouses where time-sensitive documents like receipts and invoices need to be printed continuously.

Print Quality

Print quality in dot matrix printers depends on the number of pins and the dot density per character:

- Draft Quality: Faster printing with fewer dots; letters may look rougher.

- Near-Letter Quality (NLQ): Slower printing with more dots for smoother text.

Typical Resolution:

- Ranges from 72 dpi (draft) to 240 dpi (NLQ).

- Suitable for text-heavy documents, not ideal for high-resolution images.

Carbon Copy Printing Capability

One of the most distinct advantages of dot matrix printers is their ability to create multiple copies at once:

- Impact printing allows carbon forms or multi-part stationery (up to 4–6 copies).

- Each pin strike goes through all layers, printing the same text simultaneously.

Use Case Example:

- Invoice printing in logistics companies where multiple copies for accounts, customers, and archives are required.

Continuous Paper Handling

Dot matrix printers handle continuous or fan-fold paper with ease:

- Equipped with tractor feed mechanisms for accurate alignment.

- Ideal for long reports, transaction logs, or data sheets.

Reliability and Low Running Cost

- Simple mechanical design = fewer breakdowns and easy maintenance.

- Ink ribbons last longer and cost significantly less than inkjet cartridges or toner.

- Work well in harsh environments (heat, dust, humidity).

Feature Comparison: Dot Matrix vs Modern Printers

| Feature | Dot Matrix Printer | Inkjet Printer | Laser Printer |

|---|---|---|---|

| Printing Technology | Impact (pins & ribbon) | Non-impact (ink spraying) | Non-impact (toner fusion) |

| Speed (Text Documents) | Moderate to High | Low to Moderate | High |

| Print Quality (DPI) | 72–240 | Up to 1200 | 600–2400 |

| Carbon Copy Capability | Yes (multi-part forms) | No | No |

| Operating Cost | Low | Moderate | High |

| Durability in Harsh Conditions | High | Low | Moderate |

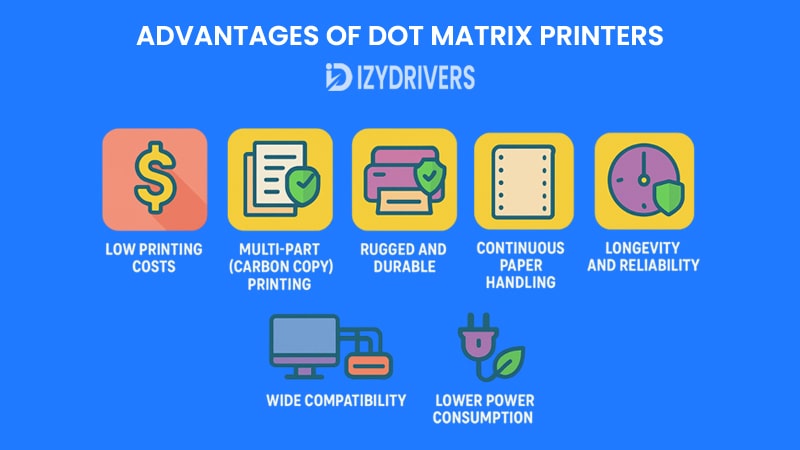

Advantages of Dot Matrix Printers

Despite being considered “old-school” compared to modern inkjet and laser printers, Dot Matrix Printers (DMPs) offer several unique advantages that make them indispensable in certain industries. Their mechanical durability, multi-copy capability, and low operating costs ensure they remain relevant even decades after their invention.

Below are the key advantages explained in detail:

Low Printing Costs

Dot matrix printers are budget-friendly both in terms of initial investment and long-term operating expenses:

- Ink ribbons are significantly cheaper than inkjet cartridges or laser toners.

- They last for thousands of pages before needing replacement.

This makes DMPs ideal for high-volume printing environments like warehouses or government offices where cost efficiency is critical.

Multi-Part (Carbon Copy) Printing

One of the most distinct advantages of dot matrix printers is their ability to print on multi-part stationery:

- With each impact, the printer imprints text through several layers of paper.

- Useful for invoices, shipping documents, and receipts where multiple copies are required simultaneously.

This is something inkjet and laser printers cannot do because they lack the physical impact mechanism.

Rugged and Durable

Dot matrix printers are designed for tough industrial environments:

- Can withstand dusty, hot, or humid conditions better than most modern printers.

- The mechanical design has fewer fragile components, reducing the risk of sudden breakdowns.

That’s why they’re commonly found in factories, banks, and warehouses even today.

Continuous Paper Handling

Equipped with tractor feed mechanisms, dot matrix printers handle continuous or fan-fold paper effortlessly.

- Perfect for long data logs, transaction reports, or inventory sheets.

- Eliminates the need to constantly reload paper.

This feature saves time and ensures uninterrupted printing during large print jobs.

Longevity and Reliability

Dot matrix printers have a reputation for being workhorses:

- They can run for millions of lines before requiring significant maintenance.

- Components like the print head and feed mechanism last much longer compared to inkjet print heads.

Wide Compatibility

Because dot matrix printers have been around for decades, they often come with:

- Universal drivers for legacy systems.

- Compatibility with older software that might not support modern printers.

This is why many financial institutions and government offices continue using them.

Lower Power Consumption

Unlike laser printers that require heating elements for fusing toner, dot matrix printers consume less electricity, making them more energy-efficient for continuous printing tasks.

Advantages and Business Benefits of Dot Matrix Printers

| Advantage | Benefit Example | Compared to Modern Printers |

|---|---|---|

| Low Running Cost | Ribbons last thousands of pages | Ink/toner costly & frequent |

| Carbon Copy Printing | Invoices, shipping documents, receipts | Inkjet/laser can’t print multi-part forms |

| Durability & Ruggedness | Works in factories, dusty warehouses | Modern printers prone to damage |

| Continuous Paper Handling | Transaction logs, large reports | Manual paper loading required |

| Reliability & Longevity | Millions of lines before major servicing | Modern printers require frequent servicing |

| Wide System Compatibility | Legacy banking software support | New printers often incompatible |

| Lower Power Consumption | Energy-efficient for long print runs | Laser printers consume more power |

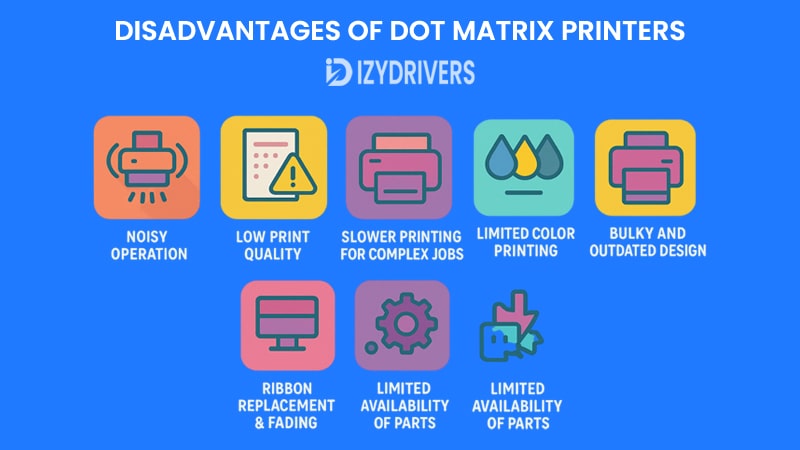

Disadvantages of Dot Matrix Printers

While Dot Matrix Printers (DMPs) offer several advantages in terms of cost-efficiency, durability, and multi-part printing capabilities, they also come with notable drawbacks. Many of these limitations explain why modern printing technologies such as inkjet and laser printers have replaced them in most consumer and office settings.

Below are the key disadvantages explained in detail:

Noisy Operation

Dot matrix printers are mechanical and impact-based, which means every pin strike creates noise:

- The print head movement and ribbon strikes are loud compared to modern printers.

- This can be disruptive in quiet office environments.

Although noise-reduction enclosures exist, they add extra cost and bulk to the setup.

Low Print Quality

Because dot matrix printers rely on patterns of dots rather than continuous lines, their resolution is limited:

- Typical resolution: 72–240 dpi (dots per inch).

- Text may look pixelated or rough compared to laser or inkjet output.

This makes them unsuitable for printing high-quality graphics or professional documents where aesthetics matter.

Slower Printing for Complex Jobs

While line printers are faster, most serial dot matrix printers print character by character:

- Printing speed decreases with denser print modes like Near Letter Quality (NLQ).

- Large images or complex forms take much longer compared to laser printers.

Limited Color Printing

Although some models support multi-color ribbons, the results are:

- Basic and limited compared to inkjet printers.

- Not suitable for color graphics or high-resolution visuals.

Bulky and Outdated Design

Dot matrix printers are often larger and heavier than modern printers:

- Require continuous paper and tractor feed mechanisms that take up space.

- The design feels outdated compared to compact inkjet and laser models.

Ribbon Replacement & Fading

Over time, the inked ribbon fades, leading to:

- Light or uneven print output as the ribbon ages.

- Frequent manual handling for ribbon replacement compared to cartridge swaps in modern printers.

Limited Availability of Parts

Since dot matrix printers are legacy technology:

- Finding replacement parts or technical support may be challenging.

- Fewer manufacturers produce ribbons and spare components today.

Limitations of Dot Matrix Printers

| Disadvantage | Practical Impact | Compared to Modern Printers |

|---|---|---|

| Noisy Operation | Disturbs office environments | Modern printers are nearly silent |

| Low Print Quality | Pixelated text, poor graphics | Laser/inkjet offer sharp output |

| Slower Printing for Complex Jobs | Long printing time for detailed documents | Laser printers much faster |

| Limited Color Printing | Basic, low-quality color output | Inkjet excels in full-color printing |

| Bulky Design | Takes up more space | Compact modern printers available |

| Ribbon Fading | Requires frequent replacement | Toner/ink cartridges last longer |

| Parts Availability | Harder to find in 2025 | Wide support for modern printers |

Applications and Use Cases of Dot Matrix Printers

Despite the rise of modern printing technologies, Dot Matrix Printers (DMPs) remain indispensable in industries where durability, low cost, and multi-copy printing are essential. Their ability to print carbon copies, handle continuous forms, and survive tough working environments makes them ideal for specialized applications.

Below are the key industries and scenarios where dot matrix printers are still widely used:

Banking and Financial Institutions

Banks and financial institutions rely on dot matrix printers for tasks such as:

- Printing transaction logs for internal records.

- Generating multi-copy deposit slips and withdrawal forms.

- Producing audit trails required for compliance and record-keeping.

Why DMPs Are Used Here:

- They handle multi-part forms efficiently.

- Cost per page remains extremely low for high-volume printing needs.

Logistics and Warehouses

In logistics companies, speed and reliability matter more than high-quality graphics:

- Dot matrix printers produce shipping labels, invoices, and delivery notes on continuous paper.

- Multi-part forms allow one print action to create copies for the printer driver, customer, and accounting department.

Key Benefits in Logistics:

- Ability to work in dusty warehouse environments.

- Durable performance during long printing sessions.

Industrial and Manufacturing Settings

Factories and industrial plants often use dot matrix printers for:

- Production logs and maintenance reports.

- Printing continuous forms during manufacturing processes.

- Real-time data printing from connected industrial systems.

Reason for Preference:

- DMPs tolerate heat, dust, and humidity better than modern printers.

- Minimal downtime ensures uninterrupted workflows.

Government Offices and Public Utilities

Dot matrix printers are still popular in government agencies and public utilities for:

- Printing electricity bills, tax receipts, and citizen records.

- Generating multi-part forms required for official documentation.

Advantages for Government Use:

- Low maintenance costs for long-term public service operations.

- High reliability in high-volume document processing environments.

Retail and Point-of-Sale (POS) Systems

Small shops, supermarkets, and service centers use dot matrix printers for:

- Billing receipts and purchase invoices.

- Printing order confirmations in food service and retail environments.

Why Retailers Still Use Them:

- Extremely cost-effective for high-frequency printing tasks.

- Continuous paper printing allows fast transaction processing.

Industry Applications: Dot Matrix Printers Use Cases

| Industry / Sector | Application Examples | Why Dot Matrix Printers Are Used |

|---|---|---|

| Banking & Finance | Transaction logs, deposit slips | Multi-copy forms, low cost, reliable printing |

| Logistics & Warehousing | Shipping labels, delivery notes | Dust resistance, continuous paper support |

| Industrial & Manufacturing | Production reports, maintenance logs | Rugged design, uninterrupted performance |

| Government & Public Utilities | Bills, tax receipts, citizen records | Cost-effective, handles large-scale paperwork |

| Retail & POS Systems | Billing receipts, order confirmations | Fast printing, low operating expenses |

Dot Matrix Printers vs. Other Printer Types

While Dot Matrix Printers (DMPs) have their unique strengths like multi-part form printing, low operating costs, and rugged durability, modern printers often outperform them in terms of speed, print quality, and functionality.

Here’s how dot matrix printers compare with other printer technologies:

vs. Laser Printers

- Laser Printers deliver high-speed printing with resolutions up to 2400 dpi, making them ideal for professional documents.

- Dot Matrix Printers offer lower costs and multi-copy printing but cannot match the sharpness or speed of lasers.

- Best Use: Laser printers are perfect for corporate offices; dot matrix suits finance and logistics for bulk, low-cost printing.

vs. All-in-One Printers

- All-in-One Printers combine printing, scanning, copying, and faxing into one machine.

- Dot Matrix Printers focus solely on printing but at a much lower cost per page.

- Best Use: All-in-One printers serve small businesses needing multiple functions, while dot matrix works best for industrial paperwork.

vs. Inkjet Printers

- Inkjet Printers excel at producing high-resolution images and color documents.

- Dot Matrix is limited to basic text and simple graphics, with significantly lower print quality.

- Best Use: Inkjet suits creative work, office reports, and photography; dot matrix is for multi-part invoices and transaction logs.

vs. Photo Printers

- Photo Printers are specialized printer for high-quality photo printing with accurate colors.

- Dot Matrix lacks the resolution and precision needed for detailed images.

- Best Use: Photo printers target photographers and designers, while dot matrix remains for business documentation.

vs. 3D Printers

- 3D Printers create three-dimensional objects using plastic, resin, or metal.

- Dot Matrix only prints on 2D paper.

- Best Use: 3D printers suit prototyping and manufacturing, whereas dot matrix handles text-based industrial records.

vs. Thermal Printers

- Thermal Printers use heat-sensitive paper to create prints, common in POS systems and ATMs.

- Dot Matrix prints last longer, as thermal prints can fade over time.

- Best Use: Thermal printers are for quick receipts and labels; dot matrix serves long-term records.

vs. Portable Printers

- Portable Printers are lightweight, compact, and often support Bluetooth or Wi-Fi printing.

- Dot Matrix printers are bulkier and require wired setups.

- Best Use: Portable printers suit fieldwork and mobile offices; dot matrix suits fixed-location operations.

Comparison Table: Dot Matrix vs. Other Printers

| Printer Type | Print Quality | Speed | Cost per Page | Multi-Copy Forms | Typical Use Case |

|---|---|---|---|---|---|

| Dot Matrix | Low (72–240 dpi) | Moderate | Very Low | Yes | Logistics, finance, manufacturing |

| Laser Printers | High (600–2400 dpi) | Fast | Moderate | No | Offices, corporate documents |

| All-in-One Printers | High | Moderate | Moderate | No | Small businesses, home offices |

| Inkjet Printers | Very High | Moderate | High | No | Graphics, photos, reports |

| Photo Printers | Very High | Moderate | High | No | Photography, creative printing |

| 3D Printers | 3D Objects | Slow | High | No | Prototyping, manufacturing |

| Thermal Printers | Moderate | Very Fast | Low | No | POS, ATMs, tickets |

| Portable Printers | Moderate | Moderate | Moderate | No | Mobile printing, fieldwork |

Conclusion

Dot Matrix Printers may be considered legacy technology, but their reliability, low cost, and multi-copy printing capabilities keep them relevant in specific industries. From banks and government offices to logistics and manufacturing plants, they excel in environments where durability and functionality outweigh aesthetics.

While modern inkjet and laser printers dominate the consumer and office markets due to their speed, quality, and design, dot matrix printers remain irreplaceable for tasks involving continuous printing, carbon copy forms, and industrial-grade durability. Understanding both their advantages and limitations helps businesses choose the right printer for their specific needs.

FAQs About Dot Matrix Printers

What is a Dot Matrix Printer used for?

Dot Matrix Printers are mainly used for printing invoices, receipts, shipping labels, transaction logs, and multi-part forms in industries like banking, logistics, government, and manufacturing.

Can Dot Matrix Printers print in color?

Some models offer multi-color ribbons, but the color quality is basic and limited, making them unsuitable for high-resolution images or full-color graphics.

Are Dot Matrix Printers still manufactured today?

Yes, several manufacturers continue to produce dot matrix printers for specialized business applications, particularly in sectors that require continuous form printing and multi-copy outputs.

How long do Dot Matrix Printers last?

With proper maintenance, a dot matrix printer can run for millions of lines before needing major repairs. They are designed for durability and long-term use.

Why are Dot Matrix Printers noisy?

They use impact printing technology where pins physically strike the paper through an ink ribbon, creating mechanical noise with each print action.