If you’ve ever hit “Print” and watched a piece of paper slide out perfectly formatted, you’ve probably taken for granted how much is happening inside that little box on your desk. The truth is, the entire printer work process is far more complex than it looks. A simple command from your computer triggers dozens of mechanical and electronic tasks inside the printer, each working in harmony to turn digital data into physical documents.

But why does understanding printer work matter? Because knowing the basics saves you time, money, and frustration. When something goes wrong—like streaky prints or endless paper jams—you’ll have a much better idea of what’s happening inside. And if you’re in the market for a new printer, this knowledge will help you choose the right technology for your needs rather than guessing based on price tags or marketing promises.

In the sections that follow, we’ll break down the entire printer work process step by step. From how data moves from your computer to the printer, to the different technologies like inkjet, laser, thermal, and even 3D printing—we’ll explain it all in plain, simple language.

Let’s start by understanding the basics of what a printer actually does before diving deeper into the mechanics behind printer work and the technology powering it.

The Basics: What a Printer Actually Does

Before diving into the technical side and exploring how printer work happens behind the scenes, it helps to start with the basics. At its core, a printer acts as a bridge between the digital and physical worlds. It takes information from your device—whether it’s a computer, smartphone, or tablet—and turns that data into a real-world document you can hold in your hands.

This might sound simple on the surface, but every time you hit “Print,” a complex chain of events kicks into motion. Multiple components, both mechanical and electronic, come together in perfect coordination to make printer work feel almost effortless. Understanding this foundation makes it easier to appreciate the different printing technologies we’ll explore later, like inkjet, laser, or thermal printers.

From Digital Data to Physical Document

Every print job starts as digital information. It could be a Word document, a PDF, or even a high-resolution image. When you send it to the printer via USB, Wi-Fi, or Bluetooth, the printer translates that data into its own internal language—often through printer drivers—so it knows exactly where to place ink or toner on the page.

This is where printer work gets fascinating. The invisible digital file is converted into precise commands for the print head, nozzles, or laser beam, depending on the printer type. These commands control exactly where each dot of ink or toner lands, ensuring sharp text, accurate colors, and consistent output. Without this process, the final print would be messy or completely blank.

Key Components That Make It All Happen

Behind every successful printer work process lies a network of essential components. The print head or drum unit handles the actual application of ink or toner. Printer Rollers move the paper through the machine at exactly the right speed, syncing with the printing mechanism. Meanwhile, the control board acts as the brain, coordinating everything from data processing to final output.

Most users never think about these parts until something goes wrong—like paper jams, streaked prints, or faded text. But once you understand how these components interact, it’s easier to troubleshoot problems and appreciate the engineering behind even the simplest-looking printer.

Different Printing Technologies Explained

Now that we understand the basics of how printer work begins, it’s time to look at the different technologies that power today’s printers. Each type uses its own unique method to turn digital data into printed output. Knowing these differences not only helps you pick the right printer but also gives you insight into why some prints look different or cost more than others.

Let’s explore the most common printing technologies you’ll find at home, in offices, and even in industrial settings.

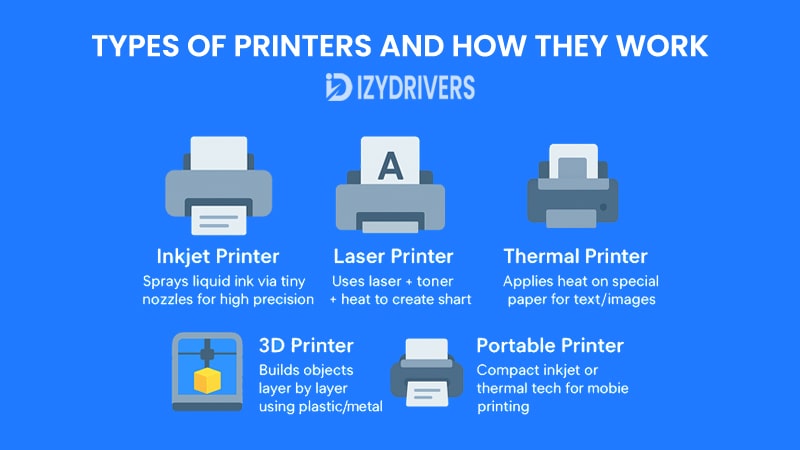

Inkjet Printers

Inkjet printers are among the most popular because of their ability to produce sharp images and vibrant colors at an affordable price. But how does the printer work in this case?

The process begins with tiny nozzles spraying microscopic droplets of liquid ink directly onto the paper. The precision is so high that even complex images with gradients and fine details come out looking smooth. Advanced models can even handle photo-quality printing that rivals professional labs.

What makes inkjet printer work impressive is how it balances quality and cost. While the printers themselves are often inexpensive, ink cartridges can be pricey over time. Still, for anyone printing photos, school projects, or colorful presentations, inkjet remains a favorite choice.

Laser Printers

Laser printers use a completely different approach. Instead of spraying ink, they rely on a laser beam and powdered toner to create images on paper. So how does this printer work so quickly compared to inkjet printers?

The laser draws the image of your document onto a drum using an electrical charge. Toner particles then stick to the charged areas. Finally, heated rollers fuse the toner onto the paper, creating a permanent print. This entire process happens in seconds, allowing laser printers to handle large volumes with ease.

Because of their speed and lower cost per page, laser printer work is ideal for offices and businesses where text-heavy documents are printed in bulk.

Thermal Printers

Thermal printers are common in places like supermarkets, ATMs, and shipping companies. Unlike inkjet or laser printers, thermal printer work doesn’t involve ink or toner at all. Instead, it uses heat to create images on special heat-sensitive paper.

The print head heats up specific areas of the paper, turning them black (or sometimes colored, depending on the paper type). The result is a fast, quiet, and low-maintenance printing process.

Because there are no moving printer cartridges or toners to replace, thermal printer work is highly reliable for receipts, labels, and barcodes where speed and durability matter most.

3D Printers

While traditional printers create flat images on paper, 3D printers take the concept of printer work to a whole new level. Instead of ink or toner, they use materials like plastic, resin, or even metal to build three-dimensional objects layer by layer.

The printer follows a digital blueprint, adding one layer of material at a time until the final product is complete. This technology has revolutionized industries like healthcare, manufacturing, and even education, where prototypes or custom tools can be created in hours instead of weeks.

3D printer work shows how far printing technology has evolved—moving beyond documents into real-world applications.

Portable Printers

For people who travel frequently or work remotely, portable printers offer a convenient solution. But how does portable printer work compared to standard models?

These compact devices often use inkjet or thermal technology, packaged in a smaller, battery-powered design. They connect via Bluetooth or Wi-Fi, letting you print documents, photos, or receipts wherever you are—without needing a full-size office setup.

The convenience of portable printer work comes at a cost, though. They’re typically slower, and consumables can be more expensive. Still, for mobile professionals, they’re a game changer.

Comparison Table: Types of Printers and How They Work

Below is a table designed for SEO and potential Google featured snippets, summarizing the main types of printers and their printer work methods:

| Printer Type | How the Printer Works | Best For | Speed | Cost per Page |

|---|---|---|---|---|

| Inkjet Printer | Sprays liquid ink via tiny nozzles for high precision | Photos, colorful documents | Moderate | Higher over time |

| Laser Printer | Uses laser + toner + heat to create sharp text | Offices, bulk text printing | Fast | Low |

| Thermal Printer | Applies heat on special paper for text/images | Receipts, labels, shipping docs | Very fast | Low |

| 3D Printer | Builds objects layer by layer using plastic/metal | Prototypes, models, manufacturing | Slow–Moderate | Depends on size |

| Portable Printer | Compact inkjet or thermal tech for mobile printing | Travel, remote work | Moderate | Moderate–High |

The Step-by-Step Process of Printer Work

Now that we’ve covered different printing technologies, let’s zoom in on what actually happens when you click “Print.” Whether you’re using an inkjet, laser, or even a portable printer, the core steps of printer work follow a logical order. Understanding this process helps you appreciate the technology and also makes troubleshooting easier when things go wrong.

We can break it into three main stages: data preparation, printing execution, and final output.

Stage 1: Data Preparation

The first step in printer work begins before any ink or toner touches the paper. When you hit the print button on your computer, the document is sent to the printer driver. This software acts like a translator between your device and the printer hardware.

The driver converts the document into a printer-friendly format, telling the machine exactly what to print, at what resolution, and on what type of paper. This is where settings like double-sided printing or color mode are applied. Without this step, the printer work would be chaotic because the hardware wouldn’t understand the raw file data.

Another part of preparation involves spooling—storing the document temporarily in a queue. This allows multiple print jobs to be handled in order, especially in offices where several people share the same printer.

Stage 2: Printing Execution

Once the data is ready, the printer work moves to the actual printing mechanism. Depending on the technology—inkjet, laser, thermal, or 3D—the process looks different, but the goal is the same: to transfer data to paper (or material) accurately.

For inkjet printers, the print head sprays ink in precise patterns, one line at a time. In laser printers, the laser beam creates an electrostatic image on a drum, which then attracts toner particles before heat fuses them to paper. Thermal printers use heat-sensitive paper, while 3D printers build layer by layer.

What makes this stage fascinating is how fast it all happens. A single sheet might pass through multiple rollers, heating elements, or nozzles in a matter of seconds, yet the printer work delivers consistent results page after page.

Stage 3: Final Output

The last stage of printer work involves finishing touches before the printed page reaches your hands. Some printers include additional features like automatic duplex printing (printing on both sides), collating pages in order, or even stapling sets together.

At this point, the printer also checks for errors—like low ink levels or paper jams—that could disrupt the final product. If everything runs smoothly, the printer delivers a clean, ready-to-use document in just a few moments.

By understanding these three stages, you can see that printer work is more than just pressing a button. It’s a carefully orchestrated sequence of digital processing, mechanical movement, and quality control.

Common Problems in Printer Work and How to Fix Them

Even though modern printers have come a long way, printer work doesn’t always run as smoothly as we’d like. From paper jams to faded prints, these hiccups can slow down productivity and lead to frustration—especially when you’re in a hurry. The good news? Most printer problems have straightforward solutions once you understand what’s happening behind the scenes.

Below, we’ll go through the most common printer issues, why they happen, and how to fix them without calling for professional help.

Paper Jams: The Classic Printer Headache

Paper jams remain one of the most frequent problems in printer work. They occur when paper feeds incorrectly, gets stuck inside rollers, or enters at the wrong angle. While they might seem random, the causes are usually predictable: overloading the tray, using wrinkled paper, or misaligned sheets.

To fix this, always start by turning off the printer before removing jammed paper to avoid damaging internal components. Open all access panels, carefully pull out the stuck sheet, and check for small torn pieces left behind. Regular cleaning of rollers and using the right paper type for your printer model can drastically reduce jams in the future.

Streaky or Faded Prints: When Quality Drops

Another common problem in printer work is streaky lines or faded text appearing on the final print. This usually points to low ink levels in inkjet printers or a nearly empty toner cartridge in laser printers. Sometimes, clogged print heads or dirty drums can also be the culprit.

Running the printer’s built-in cleaning cycle often solves this issue. For inkjet printers, removing and gently wiping the print head with a lint-free cloth can help. If you use a laser printer, replacing or cleaning the drum unit may restore sharp output. Keeping the printer in a dust-free environment also helps maintain print quality over time.

Connectivity Issues: Printer Won’t Respond

When printer work stops because the printer doesn’t respond, the problem often lies in connectivity. Wireless printers rely on stable Wi-Fi or Bluetooth connections, and any network glitch can interrupt communication between your device and the printer.

Troubleshooting usually involves checking your printer’s network settings, restarting your router, or reconnecting the printer to the Wi-Fi. For wired printers, inspect the USB or Ethernet cables for damage. Installing the latest printer drivers also resolves many connection-related headaches.

Slow Printing Speed: When Efficiency Suffers

Sometimes printer work takes longer than expected, especially when handling large files or high-resolution images. This slowdown may stem from using the highest quality print settings, outdated drivers, or limited printer memory.

Switching to draft mode for everyday documents, updating firmware, or adding extra printer memory (if supported) can dramatically improve speed. Laser printers typically handle large volumes better than inkjets, so choosing the right printer type for your workload also matters.

Error Codes and Warning Lights: Decoding the Signals

Printers often display cryptic error codes or flashing lights when printer work halts. These alerts indicate anything from low ink levels to mechanical issues.

The best approach is to consult the printer manual or manufacturer’s website for specific error codes. Many printers now come with companion apps that explain errors and offer step-by-step solutions, saving time and guesswork.

Quick reference table summarizing problems, causes, and fixes

| Common Printer Problem | Likely Cause | Quick Fix Solution |

|---|---|---|

| Paper Jam | Misaligned or wrinkled paper | Turn off printer, remove jammed paper, clean rollers |

| Streaky/Faded Prints | Low ink or clogged print heads | Clean print heads, replace ink/toner |

| Connectivity Issues | Network or driver problems | Reconnect Wi-Fi, update drivers, restart router |

| Slow Printing Speed | High-resolution settings, memory | Switch to draft mode, update firmware |

| Error Codes/Warning Lights | Hardware or software alerts | Check manual/app for error code explanation |

How to Maintain Your Printer for Long-Term Performance

Even the most advanced printer work systems need regular care to stay reliable. Just like cars need oil changes, printers require maintenance to deliver consistent quality and avoid costly repairs. Many common printing problems can be prevented with simple habits that keep both the hardware and software in top condition.

Here’s how you can make your printer last longer and keep printer work smooth and hassle-free.

Regular Cleaning Keeps Everything Running Smoothly

Dust, paper fibers, and ink residue naturally build up inside printers over time. If left unchecked, these particles interfere with rollers, print heads, and sensors, leading to paper jams or streaky prints.

A monthly cleaning routine can make a big difference. Use a lint-free cloth to wipe exterior surfaces, remove any paper debris inside, and clean rollers with isopropyl alcohol. Many printers also have a built-in cleaning function printer for print heads, ensuring the printer work stays sharp and precise.

Update Printer Drivers and Firmware

Behind the scenes, printer software plays a critical role in making printer work seamless. Outdated drivers or firmware can cause compatibility issues, slower performance, or even random errors.

Regularly checking for updates on the manufacturer’s website or enabling automatic updates ensures your printer communicates correctly with your computer and benefits from bug fixes or performance improvements.

Use the Right Paper and Ink

Not all paper and ink are created equal. Using low-quality paper or generic ink cartridges often leads to poor printer work quality, faster wear on components, and even more frequent jams.

Stick to the paper type recommended in your printer manual, especially for photo printing or duplex printing. As for ink and toner, genuine or high-quality third-party options prevent clogs, leaks, and inconsistent output.

Keep Your Printer in a Stable Environment

Where you place your printer affects its performance. Extreme heat, cold, or humidity can damage internal printer parts or affect ink consistency. For example, inkjet cartridges may dry out in hot conditions, while laser printers might struggle in overly humid areas.

Placing the printer in a clean, climate-controlled room ensures printer work stays consistent and prevents unnecessary wear on delicate parts like rollers or sensors.

Run Test Prints and Use It Regularly

Printers that sit unused for months often develop issues like dried ink or clogged nozzles. Running a simple test print every few weeks keeps ink flowing, parts lubricated, and the entire printer work system active.

Regular use is especially important for inkjet printers, where ink can dry inside the nozzles if left unused for long periods.

Printer Maintenance Checklist

| Maintenance Task | Purpose | Recommended Frequency |

|---|---|---|

| Clean print heads and rollers | Prevent clogs and paper jams | Monthly or after heavy use |

| Update drivers and firmware | Fix bugs, improve compatibility | Every 2–3 months |

| Use quality paper and ink | Ensure high-quality printer work | Always |

| Keep in stable environment | Avoid temperature/humidity damage | Ongoing |

| Run test prints | Prevent dried ink or clogs | Every 2–4 weeks |

The Future of Printer Work: Emerging Trends and Technologies

Printer technology has come a long way since the days of noisy dot-matrix machines. Today, printer work is faster, quieter, and more versatile than ever before. But innovation doesn’t stop here. Manufacturers are continuously experimenting with new technologies that make printing smarter, greener, and more connected to our digital lifestyles.

By looking at where the industry is heading, we can get a glimpse of what printing might look like in the next decade—and how printer work will adapt to changing user needs.

Smart Printers and IoT Integration

One of the biggest trends shaping the future of printer work is the rise of smart printers. These devices connect to the Internet of Things (IoT), enabling remote monitoring, automatic supply ordering, and predictive maintenance.

Imagine a printer that alerts you before ink runs out or schedules its own servicing when sensors detect early signs of wear. Businesses benefit the most, as smart printers reduce downtime, automate repetitive tasks, and even integrate with cloud platforms for seamless document workflows.

Eco-Friendly Printing Solutions

Sustainability is no longer optional—it’s becoming a standard expectation. Future printer work will focus heavily on reducing environmental impact through energy-efficient designs, recyclable materials, and eco-friendly inks or toners.

Some companies are already experimenting with water-based inks, refillable cartridge systems, and printers that automatically switch to low-power mode when idle. Over time, we can expect innovations like paper-saving AI algorithms or even zero-waste printing methods to become mainstream.

AI-Powered Print Optimization

Artificial intelligence is transforming many industries, and printer work is no exception. AI can analyze print jobs in real time, automatically adjusting settings for optimal quality and cost efficiency.

For example, an AI-enabled printer might detect whether a page needs full-color printing or if grayscale would be sufficient, saving both ink and money. AI could also predict maintenance needs, reducing unexpected breakdowns and keeping large-scale print environments running smoothly.

3D Printing Advancements

While 3D printers already exist, future versions will likely become faster, more precise, and capable of handling new materials—from bio-compatible substances for medical implants to advanced composites for aerospace engineering.

The next generation of 3D printer work might even incorporate AI-driven design tools, automatically optimizing object shapes for strength, weight, and cost before printing begins. This could make 3D printing more accessible for small businesses, schools, and hobbyists.

Cloud Printing and Remote Access

As remote work continues to grow, cloud printing will play a bigger role in printer work. Instead of needing to be in the same room—or even the same city—users can send print jobs securely over the internet.

Cloud-connected printers already allow teams in different locations to collaborate on physical documents. With better security protocols and faster networks, this trend will likely become a standard feature for both office and home printers.

Summarizing Future Trends in Printer Work

| Future Trend | How It Impacts Printer Work | Benefits for Users |

|---|---|---|

| Smart Printers + IoT | Remote monitoring, automatic supply ordering | Less downtime, higher efficiency |

| Eco-Friendly Printing | Energy-saving, recyclable materials | Lower environmental impact |

| AI Optimization | Automatic settings, predictive maintenance | Cost savings, improved reliability |

| 3D Printing Advancements | New materials, AI-driven design tools | Faster prototyping, broader adoption |

| Cloud Printing & Remote Access | Internet-based printing | Remote collaboration, easy access |

Conclusion

We’ve taken a full journey into the world of printer work, from the basics of how printers translate digital data into physical documents, to the various printing technologies, troubleshooting common problems, maintenance tips, and even a glimpse into the future of printing.

What started as a simple question—how does a printer actually work—reveals a surprisingly complex system of hardware, software, and engineering precision. Whether it’s an inkjet printing a family photo, a laser printer cranking out office reports, or a 3D printer building an object layer by layer, the process of printer work connects the digital world to our physical reality.

By understanding this process, users can make smarter buying decisions, maintain their printers more effectively, and be ready for the next wave of printing innovations.

FAQs: How Does a Printer Work?

What is the basic process of printer work?

Printer work starts with data preparation via printer drivers, moves through the actual printing mechanism, and finishes with delivering the printed page while handling errors and quality checks.

How does a laser printer work differently from an inkjet printer?

Laser printers use toner and a heated drum to fuse text and images onto paper quickly, while inkjet printers spray liquid ink in precise patterns for detailed output.

Why do printers need drivers for proper printer work?

Drivers act as translators between your computer and printer, ensuring the document’s format, resolution, and settings are accurately communicated to the hardware.

How can I keep printer work smooth and error-free?

Regular cleaning, using quality ink and paper, updating firmware, and running test prints prevent many common printing issues and keep performance consistent.

What’s next for printer work in the future?

The future of printer work will focus on AI-powered optimization, eco-friendly printing, cloud connectivity, and advanced 3D printing applications.