If you’ve ever used a printer, you probably paid more attention to the ink cartridges or toner than to the rollers hidden inside the machine. Yet, without those roller printer, your printer wouldn’t feed paper properly, apply ink evenly, or produce clean, crisp prints.

Roller printers—and the roller systems in standard printers—are the unsung heroes of the printing world. From office reports to industrial labels, they keep the entire printing process running smoothly.

In this guide, we’ll explore what roller printers are, how they work, the different types available, and expert tips for keeping them in top shape. By the end, you’ll know exactly why rollers matter and how to get the best performance out of your printer.

What is a Roller Printer?

Before we jump into functions and maintenance, let’s start with the basics this printer parts. A roller printer, or more accurately, a printer with a roller system, uses multiple rollers inside the machine to guide paper smoothly through the printing process. These rollers are responsible for picking up sheets, feeding them through the print head or imaging drum, and ensuring everything stays perfectly aligned until the final output lands in the tray.

Without this roller system, paper would jam constantly, ink would smear, and the final result would look anything but professional. In short, rollers are the behind-the-scenes workers that make sure your printer runs like clockwork.

Rollers aren’t just about moving paper from point A to point B. Their condition directly affects print quality, speed, and even the lifespan of your printer. Worn-out rollers can lead to frustrating problems like misfeeds, double feeds, or uneven print coverage. By understanding how they work and keeping them in good shape, you can save time, money, and plenty of headaches down the road.

Key Functions of Roller Printers

Roller printers—and the roller mechanisms inside conventional printers—play several essential roles in ensuring smooth, high-quality printing. While they may look like simple rubber or synthetic cylinders, each roller is designed for a specific purpose. Here are the key functions that make them so important:

Paper Feeding and Alignment

One of the most critical tasks of rollers is feeding the paper correctly into the printer. The feed rollers pick up a single sheet from the paper tray and guide it into the printing path. If these rollers slip or wear out, you might face paper jams, skewed prints, or multiple sheets entering at once.

Proper alignment is equally important. Even the tiniest misalignment can cause prints to appear crooked or text to run off the page. High-quality rollers ensure precise movement so each sheet stays perfectly straight during the printing process.

Ink or Toner Transfer Support

In laser and inkjet printers, rollers help move the sheet under the print head or imaging drum at the right speed. This ensures the ink or toner is applied evenly across the page. Without properly functioning rollers, you might notice faint streaks, uneven colors, or inconsistent text density.

The transfer rollers, in particular, play a crucial role in delivering toner from the drum unit to the paper in laser printers. Their condition can directly affect print sharpness and detail.

Ensuring Print Precision and Consistency

Printing isn’t just about speed—it’s also about precision. Rollers maintain constant pressure and timing throughout the entire printing process. They coordinate with sensors and the printer’s internal software to deliver consistent results, page after page.

This precision becomes even more important in industrial or high-volume settings, where thousands of pages might be printed in a single day. A minor roller issue could cause large-scale printing defects, leading to wasted materials and time.

Minimizing Printing Errors

From preventing paper jams to avoiding smudges, rollers are at the heart of error-free printing. Modern printers often include cleaning rollers that remove dust and leftover toner from the paper path, reducing the chance of marks or smears on the final print.

Well-maintained rollers also reduce the risk of double-feeding, where two sheets are pulled in at once. This problem can waste paper, disrupt workflows, and damage internal components if not addressed promptly.

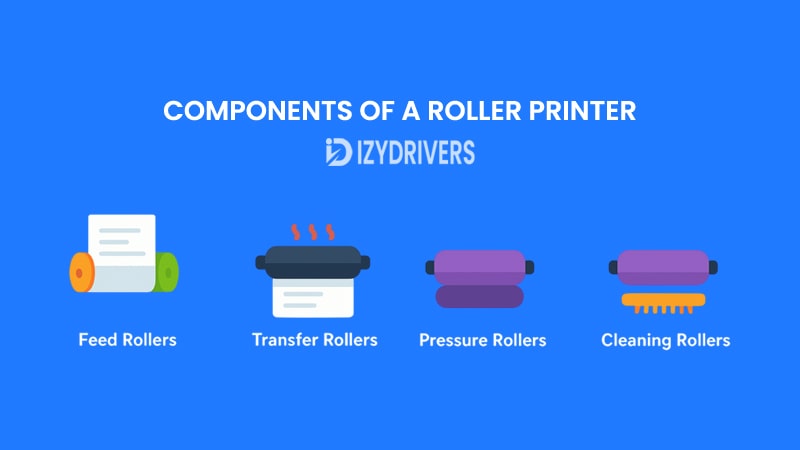

Components of a Roller Printer

Inside every printer that relies on roller systems, you’ll find several types of rollers working together in harmony. Each component serves a specific function, and understanding their roles can help you diagnose issues, improve maintenance routines, and get the best printing results possible. Let’s break down the main components:

Feed Rollers

Feed rollers are the first point of contact for paper entering the printer. Their job is to pick up one sheet at a time from the paper tray and move it into the printing path.

If feed rollers wear out, you may encounter frustrating problems like paper jams or multiple sheets feeding at once. Regular cleaning and, when necessary, replacement ensure consistent paper handling and reduce downtime.

Transfer Rollers

The transfer roller plays a critical role in laser printers. It works closely with the imaging drum, transferring toner particles onto the paper with precise timing and pressure.

A worn or dirty transfer roller can cause uneven toner application, resulting in faded prints, streaks, or missing text. Keeping this roller clean is essential for crisp, professional-quality documents.

Fuser Rollers

Fuser rollers apply heat and pressure to fuse the toner onto the paper permanently. This stage is why prints come out warm in laser printers.

Over time, fuser rollers can become coated with toner residue or develop wear marks, leading to smudges or uneven color distribution. Proper maintenance and occasional replacement keep the final prints looking sharp and clean.

Pressure Rollers

Working alongside the fuser rollers, pressure rollers ensure even pressure across the paper during the fusing process. Without adequate pressure, toner may not bond properly, causing prints to smear or peel.

High-quality pressure rollers deliver consistent results, even under demanding, high-volume printing conditions.

Cleaning Rollers

Cleaning rollers help remove excess toner, dust, and paper fibers from other rollers and internal components. By keeping the system clean, they prevent buildup that could lead to print defects or mechanical failures.

Though small and often overlooked, cleaning rollers extend the life of the entire printer by minimizing wear and tear on more expensive parts.

Types of Roller Printers

Not all roller printers are created equal. Depending on the technology they use and the environments they serve, roller printers come in different types—each with unique strengths, limitations, and ideal applications. Understanding these variations helps users and technicians select the right printer for specific needs while keeping maintenance costs under control.

Inkjet Roller Printers

Inkjet roller printers are among the most common types used in homes and small offices. They use rollers to feed paper under print heads that spray tiny droplets of liquid ink onto the page, producing sharp text and vivid images.

Best Use Cases:

- Photo printing

- Small-scale document production

- Color-rich marketing materials

Pros: Affordable initial cost, excellent color accuracy

Cons: Slower than laser printers, higher per-page costs

Laser Roller Printers

Laser roller printers rely on rollers to move paper through a laser imaging drum and fuser assembly. Toner particles are fused to the paper using heat and pressure, producing professional-quality prints at high speeds.

Best Use Cases:

- High-volume office printing

- Monochrome or color documents

- Business reports and proposals

Pros: Fast printing, low per-page cost, sharp text quality

Cons: Higher upfront cost, more complex maintenance

Thermal Roller Printers

Thermal roller printers use heat-sensitive paper and rollers to create images without ink or toner. They’re widely used in retail, logistics, and point-of-sale systems for receipts, labels, and shipping documents.

Best Use Cases:

- Receipts and barcode labels

- Shipping and logistics documentation

- Industrial labeling

Pros: No ink or toner needed, low maintenance

Cons: Limited print durability, paper sensitive to heat/light

Industrial Roller Printers

Industrial roller printers are heavy-duty machines designed for manufacturing, packaging, and large-scale labeling tasks. They handle specialized materials and work continuously for hours, often under challenging conditions.

Best Use Cases:

- Packaging labels

- Product barcodes

- Industrial signage and tags

Pros: Built for high-volume workloads, durable design

Cons: Expensive, requires professional maintenance

Specialty Roller Printers

Some roller printers are designed for niche applications, such as printing on fabrics, plastics, or metals. These are often found in commercial printing shops or manufacturing environments where standard office printers simply won’t do.

Best Use Cases:

- Fabric printing

- Plastic product labeling

- Custom signage production

Pros: Highly versatile, application-specific technology

Cons: Specialized materials and training required

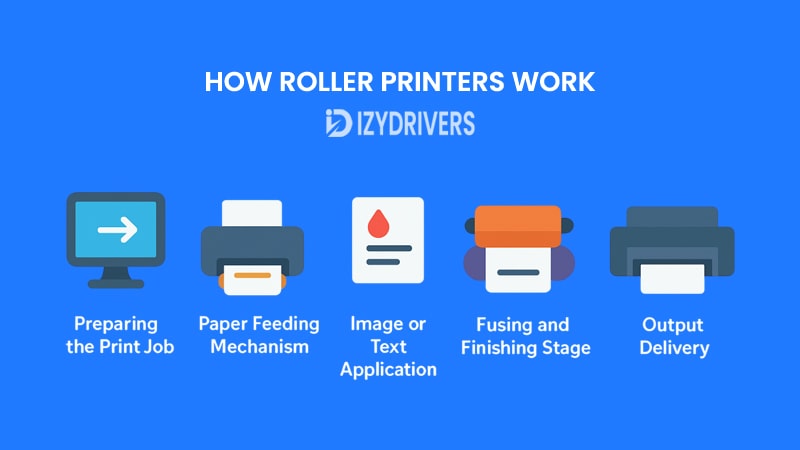

How Roller Printers Work

While roller printers may look like simple office equipment, the technology behind them involves precise coordination between rollers, sensors, and printing mechanisms. Here’s a step-by-step look at how roller printers operate, turning a digital file into a physical, high-quality print.

Preparing the Print Job

It all starts with the user sending a digital file from a computer, smartphone, or network system. The printer processes this data and converts it into instructions for the rollers, print heads, and fuser units.

Key Tasks at This Stage:

- File processing and page layout optimization

- Print resolution and color settings applied

- Communication with printer firmware for job scheduling

Paper Feeding Mechanism

Feed rollers pick up one sheet at a time from the input tray, ensuring smooth paper movement. Sensors detect paper size and alignment, reducing the risk of skewed or misfed pages.

Critical Role of Feed Rollers:

- Single-sheet feeding to avoid paper jams

- Maintaining precise alignment for accurate printing

Image or Text Application

Depending on the printer type:

- Inkjet rollers move the paper under a print head spraying tiny droplets of ink.

- Laser rollers pass the paper through an imaging drum where toner particles form the image before moving to the fuser rollers.

Timing and speed here are crucial—if paper moves too quickly or too slowly, print quality suffers.

Fusing and Finishing Stage

In laser printers, fuser rollers apply heat and pressure to bond toner to paper permanently. Inkjet printers rely on controlled drying times, while thermal printers activate heat-sensitive coatings directly.

This step ensures the final output is sharp, smudge-free, and ready for immediate use.

Output Delivery

Finally, exit rollers guide the printed sheet to the output tray. Some advanced printers include cooling rollers or finishing options like duplex printing and stapling.

Workflow How Roller Printer Works

| Step | Roller Involved | Function | Outcome |

|---|---|---|---|

| Preparing Print Job | — | File processing, resolution & layout setup | Print instructions ready |

| Paper Feeding | Feed Rollers | Picks and aligns paper | Smooth sheet entry |

| Image/Text Application | Transfer & Imaging Rollers | Applies ink or toner | Clear text/images on paper |

| Fusing & Drying | Fuser & Pressure Rollers | Heat & pressure bonding | Smudge-free, permanent prints |

| Output Delivery | Exit Rollers | Guides paper to output tray | Finished print ready for collection |

Advantages & Limitations of Roller Printers

Like any printing technology, roller printers have strengths that make them ideal for certain tasks—but they also come with a few drawbacks you need to consider. Let’s break down both sides so you can understand where roller printers shine and where they may fall short.

Advantages of Roller Printers

Smooth Paper Handling

Roller printers excel at feeding paper consistently and accurately. Thanks to their precision engineering, they significantly reduce paper jams and misalignments, making them ideal for high-volume printing environments.

This level of reliability translates into less downtime, fewer wasted sheets, and overall improved productivity.

Versatility in Printing Tasks

From simple office documents to industrial labels, roller printers can handle a wide variety of printing tasks. Specialized models can even work with materials beyond paper, such as card stock, fabric, or thermal media.

This versatility makes them useful across multiple industries, including manufacturing, logistics, and graphic design.

High-Quality Output

Because rollers maintain precise paper alignment and even toner or ink application, the print quality remains consistently sharp and professional. Whether you need crisp text or vibrant graphics, roller printers deliver.

In laser and inkjet models, this precision ensures smooth color gradients, clear images, and accurate text reproduction—even at high speeds.

Reliable Performance for High Volumes

Roller printers are built to handle large workloads efficiently. Heavy-duty rollers in industrial or office-grade printers can operate continuously without significant wear and tear, keeping performance steady under demanding conditions.

This makes them a preferred choice for businesses with bulk printing needs.

Limitations of Roller Printers

Maintenance Requirements

While roller printers are durable, their rollers require periodic cleaning and replacement. Dust, toner residue, and wear can lead to paper jams, smudging, or inconsistent print quality if ignored.

Regular maintenance is essential to keep the printer running smoothly, especially in high-volume settings.

Upfront Costs for Specialized Models

Industrial and specialty roller printers often come with higher initial costs compared to standard desktop printers. Businesses must balance these costs against the long-term savings from durability and efficiency.

For smaller offices or home users, simpler models may offer better cost-effectiveness unless advanced features are truly needed.

Bulkier Design in Some Models

Heavy-duty roller printers, particularly those for industrial use, can be larger and less portable. They require more space and sometimes professional installation, making them less suitable for compact office setups.

Expert Maintenance Tips for Roller Printers

Keeping roller printers in top condition isn’t complicated, but it does require regular attention. Proper maintenance not only ensures consistent print quality but also extends the life of the printer’s internal components, saving time and money in the long run. Here are expert-recommended tips:

Establish a Regular Cleaning Routine

Over time, dust, toner particles, and paper fibers can build up on rollers. This residue causes smudges, uneven prints, and paper jams. Use lint-free cloths or specialized cleaning sheets to remove debris.

For fuser rollers, follow the manufacturer’s instructions—some require specific cleaning agents or temperature-controlled cleaning cycles to prevent damage.

Inspect Rollers for Wear and Tear

Rollers are made from rubber or synthetic materials that wear down with use. Check them periodically for cracks, flat spots, or a slippery surface.

When rollers lose their grip, paper misfeeds and double-feeding become common problems. Replacing them promptly restores smooth performance and prevents bigger issues later.

Calibrate Printer Settings

Incorrect pressure, heat, or speed settings can cause premature roller wear and poor print quality. Many printers offer built-in calibration tools for optimal roller performance.

Run calibration tests after roller replacements or major maintenance to keep everything aligned and functioning properly.

Use Quality Consumables

Low-quality paper produces more dust and fibers, while cheap toner may leave excessive residue on rollers. Always use high-grade paper, compatible toner cartridges, and recommended cleaning supplies to reduce maintenance needs.

This small investment pays off with fewer problems and longer printer life.

Schedule Preventive Maintenance

For offices or industrial environments with heavy workloads, professional servicing every few months keeps rollers and other critical components in peak condition. Technicians can spot early signs of wear, apply lubricants, and perform deep cleaning tasks beyond what users typically handle.

Troubleshooting Common Roller Printer Problems

Even with regular maintenance, roller printers can sometimes develop problems that disrupt workflows. Knowing how to troubleshoot these issues can save time and reduce downtime. Below are the most common problems and how to address them.

Paper Jams and Misfeeds

Symptoms: Paper gets stuck, feeds at an angle, or multiple sheets are pulled at once.

Possible Causes:

- Dirty or worn-out feed rollers

- Low-quality paper or improper loading

- Incorrect paper size settings

Quick Fixes:

- Remove jammed paper carefully to avoid tearing.

- Clean feed rollers using a lint-free cloth and approved cleaning solution.

- Ensure paper is aligned correctly in the tray and matches printer settings.

Uneven or Faded Print Quality

Symptoms: Parts of the page look faint, streaked, or inconsistent.

Possible Causes:

- Dirty transfer rollers or imaging drum

- Toner or ink running low

- Incorrect temperature or pressure settings on fuser rollers

Quick Fixes:

- Clean transfer and fuser rollers regularly.

- Replace toner or ink cartridges if low or expired.

- Run the printer’s built-in calibration tool if available.

Smudging or Ghosting Effects

Symptoms: Ink smears easily, or faint images reappear on the page.

Possible Causes:

- Fuser rollers not heating correctly

- Excess toner on cleaning rollers

- Low-quality toner or incorrect paper type

Quick Fixes:

- Check fuser temperature settings in printer preferences.

- Clean or replace cleaning rollers to remove excess residue.

- Use recommended toner and paper types for your printer model.

Roller Slippage or Noise During Printing

Symptoms: Paper moves unevenly, or the printer makes unusual squeaking sounds.

Possible Causes:

- Rollers have lost grip due to wear or contamination

- Improper roller tension settings

- Lack of lubrication in moving parts

Quick Fixes:

- Inspect rollers for flat spots or cracks; replace if necessary.

- Check the printer’s tension settings in the maintenance menu.

- Apply manufacturer-approved lubricant sparingly if recommended.

Frequent Double-Feeding Issues

Symptoms: Two or more pages feed at once, wasting paper and ink.

Possible Causes:

- Worn feed rollers or pickup rollers

- Improper paper loading or bent sheets

- Incorrect printer settings for paper thickness

Quick Fixes:

- Replace pickup or feed rollers showing wear.

- Fan paper before loading to prevent sticking.

- Adjust printer settings for different paper weights.

Buying Guide: Choosing the Right Roller Printer

Not all roller printers are created equal. The right choice depends on your printing needs, budget, and the environment where the printer will be used. Below is a guide to help you narrow down your options and make a confident purchase decision.

Determine Your Printing Needs

Before diving into technical specifications, ask yourself:

- How often will I use the printer?

- What type of documents or materials will I print?

- Do I need color printing or just black and white?

For example, offices with high-volume document printing might prioritize speed and durability, while creative professionals might focus on print resolution and media compatibility.

Consider Print Volume and Speed

Print speed, measured in pages per minute (PPM), and monthly duty cycle are critical factors for busy environments.

- Low-volume users: A standard office roller printer with moderate PPM is sufficient.

- High-volume users: Look for industrial-grade printers with heavy-duty rollers built for continuous operation.

Faster speeds save time but usually come with higher price tags.

Evaluate Print Quality

Resolution, measured in DPI (dots per inch), determines how sharp and detailed the prints will be.

- Standard office use: 600 DPI is typically adequate.

- Graphics or design work: 1200 DPI or higher ensures professional-quality images and text.

Higher resolution printers often use advanced roller systems for precise paper handling and consistent results.

Check Paper Compatibility and Media Support

Some roller printers handle only standard office paper, while others support card stock, envelopes, labels, or even specialty media.

If you plan to print on multiple paper types, ensure the printer has adjustable rollers and versatile media trays.

Look at Connectivity and Software Features

Modern roller printers often include Wi-Fi, Ethernet, or Bluetooth connectivity. Some even offer mobile printing via apps like Apple AirPrint or Google Cloud Print.

Also, consider whether the printer comes with built-in maintenance tools, firmware updates, or user-friendly interfaces for troubleshooting and calibration.

Compare Total Cost of Ownership (TCO)

The initial purchase price is just one part of the equation. Factor in:

- Cost of replacement rollers and consumables

- Energy efficiency ratings

- Expected lifespan and warranty coverage

A slightly more expensive printer with lower long-term costs might be a better investment than a cheap model with high maintenance expenses.

Read Reviews and Check Support Options

Before buying, read user reviews and see if the manufacturer offers reliable customer support, spare parts availability, and clear maintenance documentation.

Brands with strong after-sales support can save you a lot of frustration when troubleshooting or replacing components.

Conclusion

Roller printers may not always be in the spotlight, but they are the backbone of smooth, reliable printing operations. From handling high volumes of documents to delivering precise, professional-quality output, these machines rely heavily on their roller systems to keep everything running seamlessly.

By understanding their functions, types, maintenance needs, and common troubleshooting steps, businesses and individual users alike can maximize printer performance while minimizing downtime and repair costs. Whether you’re investing in your first roller printer or upgrading an existing setup, making informed decisions ensures you get the most value out of your equipment.

FAQs About Roller Printers

What is the main function of rollers in a printer?

Rollers guide paper through the printing process, ensuring proper alignment, consistent speed, and even ink or toner application for high-quality prints.

How often should I clean the rollers in my printer?

For home or light office use, cleaning every 2–3 months is sufficient. High-volume environments may require monthly maintenance to prevent jams and quality issues.

What are the signs that rollers need replacing?

Frequent paper jams, double-feeding, smudges, or faded prints often indicate worn-out or damaged rollers that need replacement.

Can I replace printer rollers myself?

Yes, many printers allow users to replace rollers with basic tools. Always follow the manufacturer’s instructions to avoid damaging the printer.

Are roller printers suitable for industrial use?

Absolutely. Heavy-duty roller printers are designed for continuous operation, high print volumes, and a wide range of media types, making them ideal for industrial and commercial applications.