Imagine a world where the ideas in your mind can turn into real, physical objects within hours. That’s the promise of 3D printers — a technology that once sounded like science fiction but is now transforming industries, education, healthcare, and even personal hobbies around the globe.

From rapid prototyping for tech startups to detailed architectural models and custom medical prosthetics, 3D printers have unlocked possibilities that were hard to imagine just a decade ago. Yet for many people, the basics remain unclear: What materials do 3D printers use? Which type is best for beginners? And what key features should you look for before buying one?

In this guide, we’ll break everything down: the materials used in 3D printing, the features that matter most, the different types of 3D printers, real-world applications, and practical buying tips to help you choose the right printer for your needs. By the end, you’ll have a clear roadmap to start exploring the exciting world of 3D printing with confidence.

What is a 3D Printer?

A 3D printer is a device that creates three-dimensional objects layer by layer based on a digital design. Unlike traditional manufacturing methods that remove material from a solid block (subtractive manufacturing), 3D printing is additive manufacturing — it builds objects by adding material precisely where it’s needed.

Simply put, you start with a digital 3D model created in CAD (Computer-Aided Design) software. The printer then slices this model into thin layers and reproduces each layer in real life using materials such as plastic, resin, or even metal. When all the layers stack up, you get a complete physical object.

3D printing may seem like a cutting-edge invention, but its roots go back to the 1980s. In 1984, Charles Hull invented stereolithography (SLA) — the first 3D printing technology — paving the way for rapid prototyping.

Over the decades, costs have dropped dramatically, and the technology has evolved to include FDM (Fused Deposition Modeling) and SLS (Selective Laser Sintering), among others. Today, 3D printing is used not only in industries like aerospace and automotive but also in schools, small businesses, and even home workshops.

How 3D Printers Work?

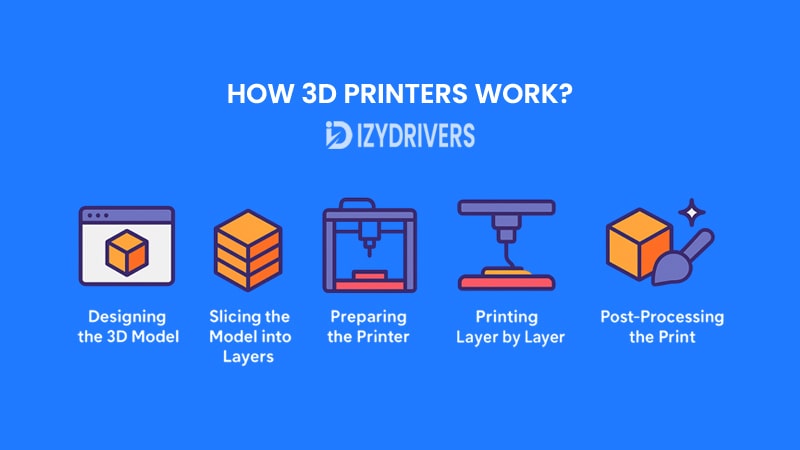

While 3D printing might look simple from the outside, the journey from a digital model to a fully printed object involves multiple interconnected stages. Each stage plays a crucial role in determining the final product’s accuracy, strength, and quality. Below is a step-by-step breakdown to help you fully understand the entire process.

Step 1: Designing the 3D Model

Every 3D printing project begins with a digital blueprint of the object. You can either design it yourself using CAD (Computer-Aided Design) software like TinkerCAD, Fusion 360, or Blender, or you can download pre-designed files from popular online libraries such as Thingiverse, MyMiniFactory, or Cults3D.

A key point to remember is that the quality of the digital design directly affects the final print. A poorly modeled file will produce defects, regardless of how good the printer is. That’s why it’s essential to ensure your design has proper geometry, no holes or gaps, and sufficient wall thickness before moving on to the next step.

Key Considerations for 3D Design

- File formats: STL, OBJ, and 3MF are the most common and widely supported formats.

- Model complexity: High-resolution designs produce better detail but require longer print times.

- Scaling and dimensions: Ensure your model fits within the printer’s build volume and intended purpose.

Step 2: Slicing the Model into Layers

Once your 3D model is ready, it needs to be converted into layered instructions that the printer can understand. This is where slicing software like Cura, PrusaSlicer, or Simplify3D comes into play.

The slicing process generates a G-code file, which serves as the printer’s roadmap. It defines every motion, temperature setting, and material deposition needed to create the object.

What Slicing Software Does:

- Breaks the 3D model into thin printable layers (commonly 0.1–0.3 mm thick).

- Sets parameters like layer height, infill density, print speed, support structures, and wall thickness.

- Optimizes the path for material efficiency and reduced print time.

Proper slicing is critical because small parameter changes can significantly impact strength, surface quality, and printing speed.

Step 3: Preparing the Printer

Before printing begins, the printer must be properly calibrated and prepped. This stage includes loading the filament or resin, leveling the print bed, and ensuring the printer’s firmware settings match the slicing parameters.

Preparation Checklist:

- Bed leveling: A flat, properly leveled bed ensures good first-layer adhesion.

- Material loading: Correct material type and diameter must be used to avoid jams or under-extrusion.

- Environmental control: Some materials require heated enclosures or specific humidity levels for optimal results.

Skipping proper preparation often leads to failed prints, warping, or layer shifting mid-process.

Step 4: Printing Layer by Layer

The actual printing process begins as the printer follows the G-code instructions to build the object one layer at a time. Depending on the technology:

- FDM printers heat and extrude plastic filament through a nozzle.

- SLA printers cure liquid resin using a laser or UV light source.

- SLS printers fuse powdered materials using a high-powered laser.

The print speed, temperature settings, and material properties all influence the final surface finish, dimensional accuracy, and part strength.

Step 5: Post-Processing the Print

Once printing is complete, many objects require post-processing to achieve the desired finish or mechanical properties.

- FDM prints may need support removal, sanding, or painting.

- SLA and resin prints typically require washing in isopropyl alcohol and additional UV curing.

- Industrial prints might undergo polishing, machining, or coating for professional applications.

Post-processing not only improves the appearance but can also enhance strength, heat resistance, and durability.

Workflow How 3D Printing Works from Design to Finished Product

| Stage | Tools/Software | Main Tasks | Key Considerations |

|---|---|---|---|

| 1. Design | CAD Software (Fusion 360, Blender) | Create or download 3D model | File format, scaling, geometry accuracy |

| 2. Slicing | Cura, PrusaSlicer, Simplify3D | Convert model into G-code layers | Layer height, infill density, supports |

| 3. Preparation | Printer Interface & Settings | Load material, level bed, calibrate printer | Material type, temperature, environment |

| 4. Printing | 3D Printer Hardware | Build object layer by layer | Print speed, resolution, adhesion quality |

| 5. Post-Processing | Sanding, UV Curing, Coating | Remove supports, finish surface, enhance part | Final appearance, mechanical properties |

Even though the workflow seems simple, several factors affect the final quality:

- Material Properties – Some materials shrink, warp, or need specific temperatures.

- Printer Calibration – Bed leveling, nozzle height, and extruder settings matter.

- Environmental Conditions – Humidity, temperature fluctuations, and dust can impact results.

3D Printing Materials

Choosing the right material for 3D printing goes beyond simply selecting the cheapest or most popular option. Each filament or resin type has its own unique physical properties, printing requirements, and ideal use cases. Below, we explore both common and advanced 3D printing materials in detail, so you can make informed decisions before starting your next project.

PLA (Polylactic Acid)

PLA, or Polylactic Acid, is widely recognized as the most beginner-friendly material in 3D printing. Made from renewable resources like corn starch and sugarcane, PLA is biodegradable and releases minimal fumes, making it suitable for home and classroom environments. It requires low printing temperatures (around 190–220°C), which means even budget-friendly printers without heated beds can handle it easily. The material produces bright, vibrant prints with a smooth finish, making it ideal for decorative objects, prototypes, and educational projects where appearance is a top priority.

However, PLA does come with some limitations. Because it has low heat resistance (softening at around 60°C) and tends to be more brittle than other plastics, it’s not ideal for functional parts exposed to high temperatures or mechanical stress. Outdoor use can also be problematic because prolonged sunlight can cause warping or fading. Despite these drawbacks, PLA remains the perfect starting point for beginners thanks to its affordability, ease of printing, and broad availability in countless colors and specialty blends like silk or glow-in-the-dark variants.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a durable and heat-resistant filament often used in engineering and industrial applications. Known for its toughness and flexibility, ABS can withstand higher temperatures and physical stress, making it a better choice than PLA for functional parts, enclosures, and mechanical components. It also has excellent post-processing potential; parts can be sanded, drilled, or chemically smoothed with acetone vapor for a professional finish.

On the downside, ABS requires higher printing temperatures (230–260°C) and a heated bed to prevent warping during cooling. It also emits fumes during printing, so good ventilation is essential. Beginners may find ABS harder to work with compared to PLA because it demands precise temperature control and stable environmental conditions. Still, for projects where strength, durability, and thermal resistance are critical, ABS is a reliable material favored by professionals and hobbyists alike.

PETG (Polyethylene Terephthalate Glycol)

PETG combines the strength and heat resistance of ABS with the ease of printing close to PLA, making it a versatile choice for many users. It offers excellent layer adhesion, low warping, and chemical resistance, so printed parts are both durable and moisture-resistant. PETG is also food-safe in many cases (though check manufacturer specifications) and ideal for items like water bottles, storage containers, or mechanical components exposed to light wear and tear.

While PETG prints at moderate temperatures (220–250°C) and is generally user-friendly, it does tend to string or ooze more than PLA, which may require fine-tuning printer retraction settings. Additionally, it’s slightly less rigid than ABS, so for parts under heavy mechanical stress, alternatives like nylon or carbon fiber-reinforced filaments may be better. Overall, PETG hits a sweet spot between strength, durability, and ease of use, making it one of the most popular filaments for intermediate users.

Resin (Photopolymer)

Resin is primarily used in SLA (Stereolithography) or MSLA (Masked SLA) printers rather than FDM printers. It excels in producing extremely high-detail prints with smooth surfaces, making it the go-to material for applications like jewelry casting, dental models, tabletop miniatures, and prototype designs requiring fine precision. Because resin printing uses UV light to cure liquid resin layer by layer, it achieves much finer resolutions than most filament-based technologies.

However, resin printing comes with additional considerations. Uncured resin is toxic and messy to handle, requiring gloves, protective eyewear, and well-ventilated spaces. Prints also need post-processing steps such as alcohol cleaning and UV curing to reach full strength. Resin materials are generally more expensive, and printers have smaller build volumes compared to FDM models. Despite these challenges, the visual quality and precision offered by resin make it indispensable for professionals who need accurate, highly detailed parts.

Nylon

Nylon is a tough, flexible, and wear-resistant material widely used in industrial settings. It offers excellent durability and impact resistance, making it perfect for functional parts like gears, hinges, and mechanical components that face friction or repeated stress. Nylon also has a naturally smooth, low-friction surface, so moving parts operate more efficiently compared to prints made from PLA or ABS.

The trade-off is that nylon can be challenging to print because it requires precise temperature control (240–260°C) and tends to absorb moisture from the air, which can affect print quality. Storing it in airtight containers with desiccants is a must. Additionally, some printers may need specialized nozzles to handle nylon’s higher printing temperatures. For experienced users seeking professional-grade strength and durability, nylon remains a top-tier filament choice.

Carbon Fiber-Reinforced Filament

Carbon fiber-reinforced filaments combine standard thermoplastics like PLA, ABS, or Nylon with chopped carbon fibers to produce lightweight yet incredibly stiff prints. The result is a material with excellent strength-to-weight ratios, making it popular in industries like automotive, aerospace, and robotics where high performance and reduced weight are critical.

Printing with carbon fiber filaments requires caution because the fibers are abrasive and can quickly wear down standard brass nozzles. Hardened steel or ruby-tipped nozzles are often recommended. Additionally, this material is pricier than basic filaments and demands well-calibrated printers for optimal results. When strength, precision, and weight reduction are top priorities, carbon fiber-reinforced materials stand out as a premium choice.

Metal Filaments (Steel, Titanium, etc.)

Metal 3D printing uses filaments or powders containing real metal particles, allowing the production of strong, heat-resistant, and functional metal parts. Materials like stainless steel, titanium, or aluminum enable prototyping for aerospace, automotive, and medical industries where durability and performance matter most.

However, true metal 3D printing often requires specialized industrial printers like DMLS (Direct Metal Laser Sintering) or Binder Jetting systems, which are far more expensive than consumer-grade options. Post-processing steps such as sintering or machining are typically needed to achieve final strength and dimensional accuracy. Because of the cost and complexity, metal 3D printing remains primarily within professional or industrial applications rather than hobbyist use.

3D Printers Material Properties Comparison

| Material | Strength | Heat Resistance | Ease of Printing | Cost | Best Use Cases |

|---|---|---|---|---|---|

| PLA | Medium | Low | Very Easy | Low | Prototypes, Decorative Models |

| ABS | High | High | Moderate | Low-Medium | Functional Parts, Engineering |

| PETG | High | Medium | Easy | Medium | Food Containers, Outdoor Objects |

| Resin | Medium | Low-Medium | Moderate | Medium-High | Miniatures, Dental, Jewelry |

| Nylon | Very High | Medium-High | Moderate | Medium-High | Gears, Mechanical Parts |

| Carbon Fiber Filament | Very High | High | Moderate | High | Automotive, Aerospace |

| Metal Filaments | Extremely High | Very High | Difficult | Very High | Industrial, Aerospace, Medical |

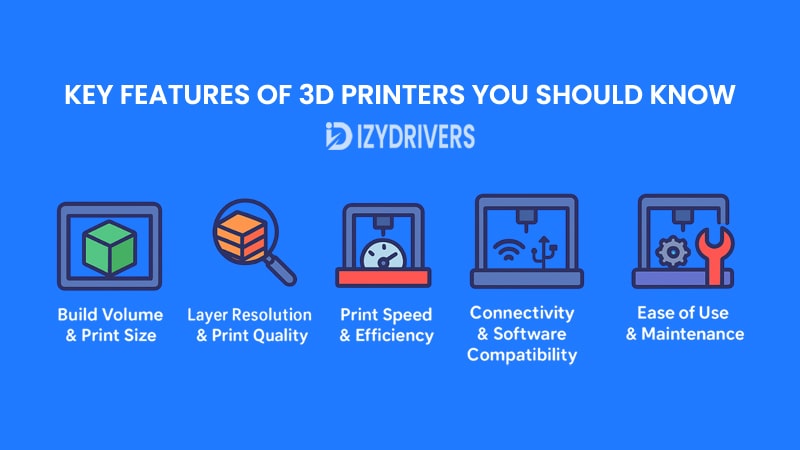

Key Features of 3D Printers You Should Know

Before buying a 3D printer or starting your first project, it’s essential to understand the key features that affect print quality, speed, ease of use, and overall performance. These features can make the difference between a smooth 3D printing experience and constant frustration with failed prints.

Build Volume & Print Size

Build volume refers to the maximum physical size a 3D printer can produce in a single job. Measured in millimeters (e.g., 220 × 220 × 250 mm), it defines the width, depth, and height available for printing. Larger build volumes allow you to print bigger models or multiple parts at once, making them ideal for professional projects or industrial prototyping.

However, bigger isn’t always better for beginners. Printers with large build volumes often cost more, require more space, and may take longer to heat and calibrate. For hobbyists or students, a mid-range build volume is usually enough to create models, miniatures, and functional parts without sacrificing cost-efficiency or convenience.

Layer Resolution & Print Quality

Layer resolution, measured in microns (µm), determines the thickness of each printed layer. The smaller the layer height, the finer the detail and the smoother the surface finish of the final object. For example, a 100-micron print has more visible layer lines compared to a 50-micron print, which will appear smoother and more professional.

High-resolution printing is perfect for intricate designs like jewelry or detailed prototypes, but it comes with trade-offs. Smaller layers mean longer print times because the printer must produce more layers for the same object height. Beginners often find a balance at 100–200 microns, where print quality is decent without excessive print times.

Print Speed & Efficiency

Print speed defines how fast the printer moves while extruding material, directly affecting how long it takes to complete a project. Most consumer 3D printers operate at speeds between 40–100 mm/s, though some high-end models can go faster.

That said, faster printing isn’t always better. Higher speeds can cause quality issues like stringing, inaccurate dimensions, or weak layer adhesion. Finding the right balance between speed and quality is key, especially for functional parts that require strength and durability.

Connectivity & Software Compatibility

Modern 3D printers come with multiple connectivity options, including USB, SD card, Wi-Fi, and even cloud-based printing platforms. Wireless connectivity allows you to send designs directly from your computer or smartphone, while traditional USB/SD methods are often more stable and less prone to interruptions.

Equally important is software compatibility. Slicing software like Cura, PrusaSlicer, or Simplify3D converts 3D models into printer-readable G-code. Choosing a printer that works smoothly with popular slicers gives you access to better settings, profiles, and community support, making the printing process easier to learn and troubleshoot.

Ease of Use & Maintenance

For beginners, user-friendly features like auto bed leveling, touchscreen interfaces, and pre-configured print profiles can make a huge difference. These features reduce the learning curve and minimize failed prints caused by improper calibration or setup errors.

Maintenance is another key factor to consider. Printers with modular designs, easy-to-clean nozzles, and accessible replacement parts are far less frustrating to own in the long run. Spending a little extra on a printer with better usability features often saves time, money, and headaches over its lifespan.

Types of 3D Printers

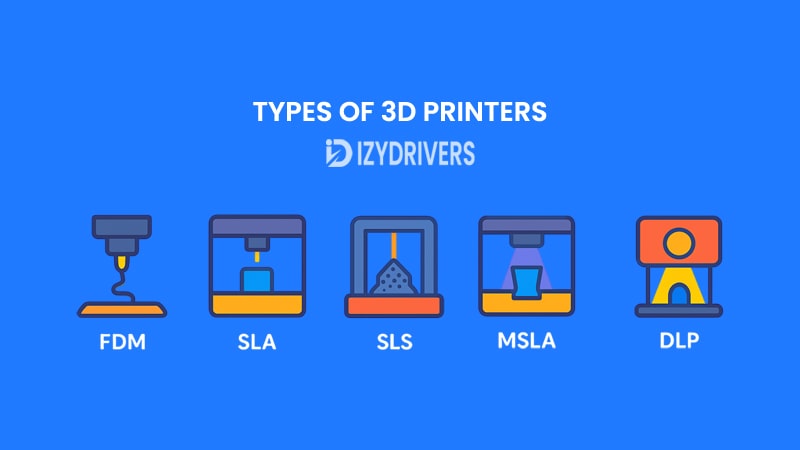

Not all 3D printers work the same way. Different printing technologies use different methods to build objects layer by layer, and each comes with its own strengths, weaknesses, and ideal applications. Understanding these types will help you choose the right printer for your needs, whether you’re a hobbyist, educator, or professional.

FDM (Fused Deposition Modeling)

FDM printers are the most common and affordable type of 3D printers on the market. They work by heating thermoplastic filaments like PLA or ABS and extruding the molten material through a nozzle to build the object layer by layer. Thanks to their simplicity and low cost, FDM printers are often recommended for beginners and hobbyists.

However, FDM prints tend to have visible layer lines and may require post-processing to achieve smoother surfaces. Print strength and resolution also depend on factors like nozzle size, layer height, and print speed. Still, for projects like prototypes, functional parts, and DIY creations, FDM printers offer excellent value for money.

SLA (Stereolithography)

SLA printers use liquid resin and ultraviolet (UV) light to create highly detailed prints with smooth surfaces. A laser cures the resin layer by layer, producing objects with far finer resolution than FDM printers can typically achieve. This makes SLA ideal for applications like jewelry, dental molds, and intricate miniatures where precision matters most.

The downside of SLA printing is the messy post-processing: prints need cleaning in isopropyl alcohol and additional curing under UV light to reach full strength. Resin materials are also more expensive, and the printing environment must be well-ventilated due to fumes. Despite this, SLA remains the top choice for professionals who prioritize detail over speed or cost.

SLS (Selective Laser Sintering)

SLS printers use a laser to fuse powdered materials, often nylon or polyamide, into solid layers. Because the surrounding powder acts as a natural support structure, SLS can print complex geometries without the need for additional supports. This makes it popular for producing functional prototypes and small-batch production parts.

Unlike FDM or SLA, SLS printers are significantly more expensive and usually found in industrial or professional settings. The powder-handling process can also be messy and requires safety precautions. Still, SLS offers excellent mechanical strength and design flexibility, making it invaluable in engineering, aerospace, and manufacturing applications.

MSLA & DLP (Masked SLA and Digital Light Processing)

MSLA and DLP printers are variations of resin-based technologies similar to SLA but use different light sources. MSLA printers employ an array of UV LEDs with an LCD masking screen, while DLP uses a digital projector to cure entire layers at once. These methods often result in faster print times compared to traditional SLA printers.

Print quality is comparable to SLA, but costs and speeds vary depending on the model. Like SLA printers, they require post-processing steps, including cleaning and curing, as well as careful handling of liquid resin. For users who need high-detail prints with shorter production times, MSLA and DLP offer a solid balance between speed and quality.

Comparison of Types of 3D Printers

| Printer Type | Material Used | Print Quality | Cost | Best For |

|---|---|---|---|---|

| FDM | Thermoplastic Filaments | Medium | Low | Beginners, DIY Projects, Prototypes |

| SLA | Liquid Resin | Very High | Medium-High | Jewelry, Dental Models, Miniatures |

| SLS | Powdered Nylon/Polymers | High | High | Engineering, Industrial Prototyping |

| MSLA/DLP | Liquid Resin | Very High | Medium-High | High-Detail Prototypes, Fast Production Runs |

Real-World Applications of 3D Printers

3D printing is no longer just a futuristic concept; it has become a practical tool across industries, revolutionizing the way we design, prototype, and manufacture products. From healthcare to aerospace, the versatility of 3D printers continues to expand, opening new possibilities for innovation and efficiency.

Prototyping and Product Development

One of the earliest and most widespread uses of 3D printing is rapid prototyping. Traditional manufacturing methods often take weeks or even months to produce a prototype, especially when custom molds or tools are required. With 3D printing, engineers and designers can transform a digital model into a physical object in just hours or days, accelerating the entire development cycle.

This speed not only saves time but also enables iterative design improvements. Teams can quickly test different versions, gather feedback, and refine the product before mass production. As a result, companies reduce costs, shorten time-to-market, and minimize risks associated with design flaws.

Healthcare and Medical Applications

The healthcare industry has embraced 3D printing in remarkable ways. Surgeons now use 3D-printed anatomical models to plan complex procedures, allowing for greater precision and reduced surgical risks. Customized prosthetics and orthotics can be produced to fit individual patients perfectly, improving comfort and functionality.

Even more groundbreaking is the development of bioprinting, where living cells are used to create tissue-like structures. Although still in its early stages, this technology has the potential to revolutionize organ transplants, regenerative medicine, and drug testing in the future.

Education and Research

Schools and universities are integrating 3D printing into classrooms and laboratories to enhance STEM education. Students can bring abstract concepts to life by printing 3D models of molecules, historical artifacts, or architectural structures. This hands-on learning approach helps foster creativity, problem-solving skills, and technical expertise.

In research settings, 3D printing allows scientists to create custom lab equipment or experimental models quickly and affordably. This flexibility accelerates innovation across disciplines, from engineering to biology.

Manufacturing and Small-Batch Production

3D printing enables on-demand manufacturing, reducing the need for large inventories and expensive tooling. Companies can produce small batches of customized products without the high setup costs of traditional manufacturing processes.

Industries like automotive and aerospace use 3D printing for lightweight components, complex geometries, and parts that would be impossible to make using conventional methods. This shift towards additive manufacturing helps companies reduce waste, lower costs, and achieve greater design freedom.

Art, Design, and Fashion

Artists, designers, and fashion innovators are leveraging 3D printing to push creative boundaries. Intricate sculptures, custom jewelry, and avant-garde fashion pieces can be produced with stunning detail and precision that traditional methods often cannot achieve.

Moreover, 3D printing supports personalization at scale. Designers can create one-of-a-kind pieces tailored to individual preferences, opening new possibilities in luxury fashion, interior design, and creative industries.

Buying Tips for 3D Printers

Choosing the right 3D printer can feel overwhelming, especially with so many options available on the market. The best choice depends on your budget, skill level, and intended use. Below are key factors to consider before making your purchase.

Define Your Purpose and Goals

Before diving into specifications, clarify what you want to achieve with your 3D printer. Are you a beginner looking to learn the basics, a hobbyist creating models at home, or a professional producing prototypes for business use? Your goals will determine whether you need a simple entry-level printer or a high-end industrial model.

For instance, students or educators may prefer a user-friendly and low-maintenance printer, while engineers might prioritize accuracy, build volume, and material compatibility. Clearly defining your purpose will help narrow down choices and prevent overspending on unnecessary features.

Set a Realistic Budget

3D printers range from affordable beginner models under $300 to professional-grade machines costing thousands of dollars. Besides the initial cost, consider ongoing expenses such as filament, resin, maintenance parts, and potential upgrades.

It’s often better to start with a mid-range printer offering reliability and decent print quality rather than the cheapest model available. Entry-level machines might be tempting, but they often require more troubleshooting and upgrades over time.

Check Material Compatibility

Not all 3D printers can handle every material. FDM printers typically work with PLA, ABS, and PETG, while SLA printers use resin, and SLS printers work with powders like nylon. Some advanced filaments, like carbon-fiber composites or flexible TPU, require specific hardware features like hardened nozzles or direct-drive extruders.

Choosing a printer compatible with multiple materials gives you flexibility for future projects. It ensures you won’t be stuck with limitations if you decide to experiment with new applications or stronger materials later on.

Look for User-Friendly Features

Features such as auto bed leveling, filament runout sensors, touchscreen interfaces, and Wi-Fi connectivity make the printing experience smoother, especially for beginners. These features reduce manual calibration errors, prevent failed prints, and allow remote monitoring of progress.

Some printers also offer pre-configured print profiles and integration with slicing software for a hassle-free setup. This is particularly useful for users who want to focus on designing and printing rather than troubleshooting hardware issues.

Read Reviews and Join Communities

Before making a final decision, check user reviews, online forums, and social media groups dedicated to 3D printing. Real-world feedback often reveals details that product descriptions don’t, such as ease of assembly, reliability, and customer support quality.

Joining online communities can also provide valuable tips, troubleshooting guides, and recommended settings for your specific printer model. This network of enthusiasts and professionals can save you time and frustration as you learn and grow in 3D printing.

3D Printers vs. Other Printer Types

While 3D printers have revolutionized manufacturing and prototyping, they are very different from traditional 2D printers used for everyday tasks. Let’s compare 3D printers with various common printer types to understand how each serves a unique purpose.

3D Printers vs. Laser Printers

Laser printers use a laser beam to transfer toner onto paper, producing fast, high-quality text and graphics. They are best for office environments requiring large volumes of documents at low per-page costs.

In contrast, 3D printers build three-dimensional physical objects from digital models. Instead of ink or toner on paper, they use materials like plastics, resins, or metals to create real-world items layer by layer.

3D Printers vs. All-in-One Printers

All-in-one printers combine printing, scanning, copying, and sometimes faxing in one device. They are multifunctional machines designed for home offices and businesses needing a wide range of document-handling features.

3D printers, on the other hand, specialize in fabricating physical parts, not paper documents. While some advanced 3D printers may include integrated cameras or monitoring systems, their primary role is manufacturing, not documentation.

3D Printers vs. Inkjet Printers

Inkjet printers spray tiny droplets of liquid ink directly onto paper to produce vibrant colors and sharp images. They excel at photo printing and small-scale document production with high resolution.

3D printers operate on a completely different principle, depositing or curing material in layers to build solid, tangible objects rather than flat images. This makes them suitable for engineering, prototyping, and creative manufacturing rather than traditional office use.

3D Printers vs. Photo Printers

Photo printers are a subset of inkjet printers optimized for high-quality photographic output on specialized printer paper. They deliver exceptional color accuracy and detail for professional printer for photography or graphic design.

3D printers, meanwhile, serve industries and hobbyists looking to produce functional or decorative 3D objects rather than 2D images. The two technologies rarely overlap in practical use cases.

3D Printers vs. Dot Matrix Printers

Dot matrix printers use a print head with pins striking an ink ribbon to form characters on paper. Though outdated, they remain in use for carbon copy forms, invoices, and industrial settings where low-cost, continuous printing is needed.

Unlike the noisy, text-based dot matrix printers, 3D printers use additive manufacturing technology to create physical items with precision, often requiring digital models and specialized materials.

3D Printers vs. Thermal Printers

Thermal printers apply heat to special thermal paper to create images or text. They are common in retail, shipping, and point-of-sale systems due to their speed and low maintenance requirements.

While thermal printers create 2D receipts or labels, 3D printers fabricate solid objects, serving an entirely different role in manufacturing, healthcare, and engineering.

3D Printers vs. Portable Printers

Portable printers are compact, lightweight devices designed for printing documents on the go, often using Bluetooth or Wi-Fi connectivity. They prioritize mobility and convenience over speed or large-scale production.

In contrast, 3D printers are typically stationary machines requiring stable environments, specialized materials, and longer production times to create three-dimensional models.

Comparison 3D Printers vs. Traditional Printer Types

| Printer Type | Primary Output | Use Case | Technology | Cost Range |

|---|---|---|---|---|

| 3D Printer | Physical 3D objects | Prototyping, Manufacturing | Additive Manufacturing | Medium–High |

| Laser Printer | Text & graphics on paper | Office, bulk document printing | Toner + Laser Technology | Low–Medium |

| All-in-One Printer | Print, scan, copy, fax | Home & office multifunction tasks | Inkjet or Laser Technology | Low–Medium |

| Inkjet Printer | High-quality images & text | Home, small businesses, photos | Liquid Inkjet Technology | Low–Medium |

| Photo Printer | Professional photo prints | Photography & graphic design | Specialized Inkjet Technology | Medium |

| Dot Matrix Printer | Text-based forms & invoices | Industrial, multi-part documents | Impact Printing Technology | Low |

| Thermal Printer | Receipts & labels | Retail, logistics, POS systems | Heat-Sensitive Thermal Technology | Low |

| Portable Printer | On-the-go document printing | Travel, field work | Inkjet or Thermal Technology | Low–Medium |

Conclusion

3D printing has evolved from a niche technology into a mainstream manufacturing and prototyping tool used across industries. From basic hobbyist projects to cutting-edge medical applications, its versatility continues to expand as materials, printer types, and software improve each year.

For beginners, the key is to start simple: understand the basic workflow, experiment with affordable materials like PLA, and gradually explore more advanced features and printer types. Professionals, on the other hand, can leverage high-end printers and specialized materials to achieve greater precision, functionality, and production speed.

Ultimately, the right 3D printer depends on your goals, budget, and technical expertise. By understanding the types of printers, key features, materials, and real-world applications outlined in this guide, you can make an informed decision and fully unlock the potential of 3D printing technology.

FAQs About 3D Printers

What is the easiest 3D printer for beginners?

For beginners, FDM printers such as the Creality Ender series or Prusa i3 models are often recommended. They are affordable, widely supported by communities, and easy to set up with plenty of online tutorials available.

Which material is best for 3D printing functional parts?

Materials like ABS, PETG, or Nylon are better suited for functional parts because they offer higher strength, heat resistance, and durability compared to PLA, which is more suited for decorative or prototype models.

How much does it cost to maintain a 3D printer?

Maintenance costs depend on the printer type and usage frequency. Expect to spend on filaments or resin, replacement nozzles, and occasional upgrades. On average, hobbyist users may spend $20–50 per month on consumables.

Can 3D printers make food-safe objects?

Yes, but with limitations. PETG is commonly considered food-safe, but you must ensure the printer uses food-safe nozzles and avoid cross-contamination. Post-processing methods like applying a food-safe coating may also be necessary.

Is 3D printing profitable as a business?

Absolutely. Many entrepreneurs use 3D printing for custom products, prototyping services, or small-scale manufacturing. Success depends on identifying niche markets, ensuring print quality, and managing production costs effectively.