A printer can have all the latest features, but if the printhead fails, everything comes to a halt. The printhead is the part that transforms digital files into real, physical prints by spraying precise amounts of ink onto paper. Whether it’s an inkjet model at home or a heavy-duty office printer, the printhead does the heavy lifting behind every crisp document or photo you print.

Over time, Print Head face issues like clogging, misalignment, or ink smudging. Without proper care, these problems can turn a reliable printer into a frustrating one. This guide takes a closer look at what a printhead is, the types available, common problems, and practical maintenance tips—so you can keep your printer running smoothly and avoid costly repairs.

What Is a Printhead?

A printhead is the core component in a printer responsible for transferring ink onto paper. Without it, no image or text could be created. Sitting between the ink cartridges and the paper, the printhead contains tiny nozzles—sometimes in the thousands—that spray microscopic drops of ink with incredible precision.

Think of it as the painter’s brush in the world of printing. Instead of bristles, it uses electronically controlled nozzles to place ink exactly where it’s needed. Modern printers use advanced technology so the printhead can produce sharp text, vibrant photos, and professional-quality graphics on demand.

Printhead vs Print Head: Are They the Same Thing?

You might see both printhead and print head used in product manuals or online guides. Technically, they refer to the same part. The difference is mostly in naming convention rather than function.

- Printhead (single word) is the term most commonly used by printer manufacturers and in technical documentation.

- Print head (two words) sometimes appears in casual conversations or older manuals, but it means the same thing.

Anatomy of a Printhead: Inside the Technology

A printhead might seem like just another part of a printer, but inside, it’s a miniature engineering marvel. Understanding its internal components helps explain why print quality can vary so much between different printers and why maintenance matters.

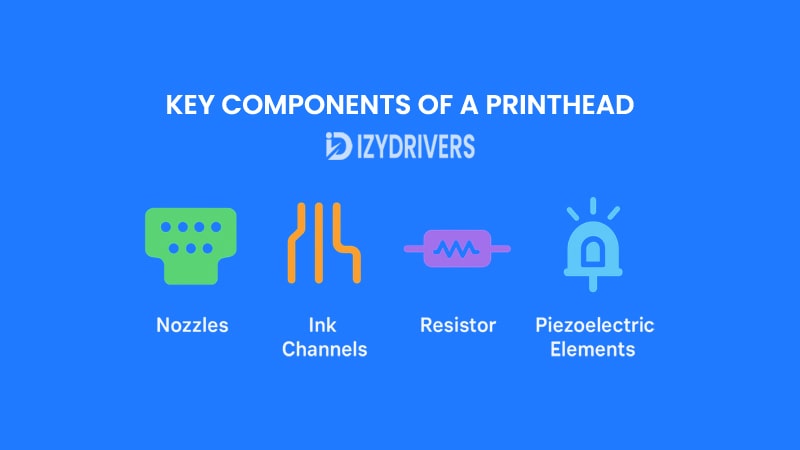

Key Components of a Printhead

Inside every printhead, there are several critical components working together to transfer digital images onto paper with microscopic precision:

- Nozzles: These are tiny openings—sometimes smaller than a human hair—through which ink droplets are ejected onto the paper. A single printhead can have hundreds or even thousands of nozzles arranged in precise patterns to handle different colors and resolutions.

- Ink Channels: Acting like small pipelines, these channels guide ink from the cartridges to the nozzles. They ensure a steady, uninterrupted flow so that no air bubbles or blockages disrupt the printing process.

- Resistor or Piezoelectric Elements: Depending on the technology used, these components control how ink is fired. In thermal Print Head, resistors heat the ink to form vapor bubbles that force droplets out. In piezoelectric Print Head, crystals change shape under electrical signals to push ink through the nozzles.

Each component has a specific role, but it’s the way they work together that determines the final output quality.

How Each Component Works Together

When you click “Print,” the printer sends digital instructions to the printhead. The ink channels carry ink from the cartridges into small chambers right behind the nozzles. At the same time, the resistors or piezoelectric elements respond to electrical signals, controlling when and how each nozzle fires.

This synchronized process ensures that every droplet lands on the paper in the correct location, forming sharp lines, vivid colors, and accurate text. If even one component fails—like a clogged nozzle or an overheated resistor—you’ll see missing lines, blurry text, or uneven colors in the final print.

Why Printhead Design Affects Print Quality?

Not all Print Head are created equal. The size of the nozzles, the number of ink channels, and the precision of the firing mechanism directly influence how detailed the final print will be.

- Nozzle Density: More nozzles mean finer detail and faster printing because more ink droplets can be fired at once.

- Channel Design: Well-designed channels maintain consistent ink flow, preventing streaks or color variations.

- Firing Accuracy: Better resistor or piezo control allows for smaller, more consistent droplet sizes, which results in smoother gradients and sharper text.

High-end printers typically have Print Head with advanced designs that support ultra-high resolution and fast print speeds, while budget models may compromise on these features to reduce cost.

How a Printhead Works: Step-by-Step Process

A printhead may look small, but inside, a precise and complex process turns liquid ink into sharp, detailed images or text on paper. Understanding this workflow helps users appreciate why proper maintenance matters and why Print Head are so important for printing quality.

Ink Flow Mechanism

The process begins with the ink cartridges. Each cartridge stores a specific color of ink—usually cyan, magenta, yellow, and black (CMYK). When you send a print command, the printer’s internal pump draws ink from the cartridges through narrow ink channels directly into the printhead.

Inside the printhead, the ink is held in tiny reservoirs before it is ejected through nozzles. The design ensures that the ink flow is steady and consistent so that every droplet reaches the paper at the right moment. Any disruption in this flow, such as air bubbles or blockages, can lead to poor print quality or missing lines.

Nozzle Firing Technology

Once the ink reaches the nozzles, precision technology takes over. Each nozzle can be as small as a fraction of a human hair, and there can be hundreds or even thousands on a single printhead.

Two main technologies control how the ink is fired:

- Thermal firing: Heats the ink to form a vapor bubble that pushes the droplet out.

- Piezoelectric firing: Uses crystals that change shape under electricity to push the ink out.

Both methods ensure the droplets are the right size and land exactly where they should on the page. Even tiny variations can affect print sharpness, color accuracy, and overall image quality.

Paper and Printhead Interaction

Finally, the paper moves under the printhead while the nozzles release ink droplets in carefully timed patterns. The speed of the paper feed, the distance between the printhead and the paper, and the precision of the nozzles all determine how sharp and clean the final print looks.

High-quality printers adjust these parameters automatically, while cheaper models may require manual calibration if prints start looking blurry or uneven.

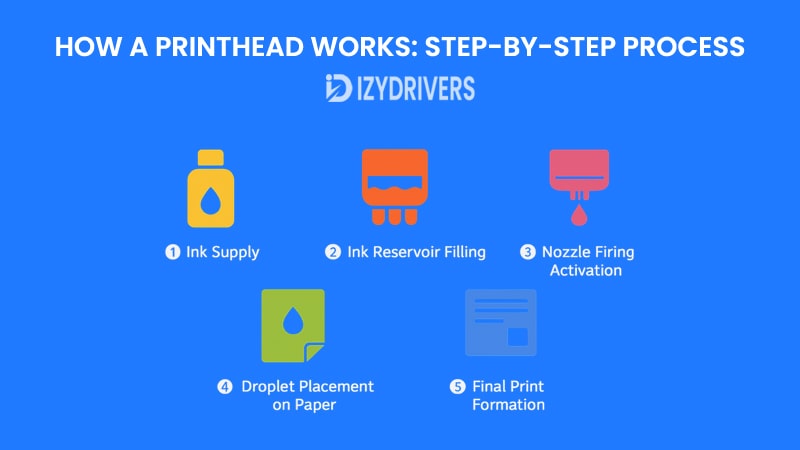

Step-by-Step Workflow of How a Printhead Works

| Step No. | Process Stage | What Happens | Key Factors Affecting Quality |

|---|---|---|---|

| 1 | Ink Supply | Ink moves from cartridges to the printhead via channels | Ink quality, cartridge condition |

| 2 | Ink Reservoir Filling | Ink is stored briefly before being ejected | Consistent flow, no air bubbles |

| 3 | Nozzle Firing Activation | Thermal or piezoelectric technology ejects droplets | Nozzle precision, firing speed |

| 4 | Droplet Placement on Paper | Ink lands on moving paper in exact positions | Paper speed, printhead distance, nozzle accuracy |

| 5 | Final Print Formation | Image or text appears with correct colors and sharpness | Calibration, alignment, and maintenance |

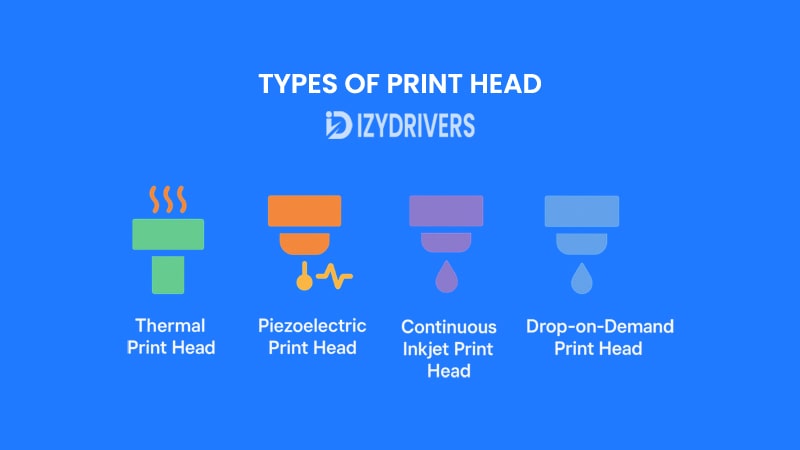

Types of Print Head

Not all Print Head are the same. Different printers use different technologies to suit various needs—from everyday document printing to professional photo production. Understanding the types of Print Head helps you pick the right printer and care for it properly.

Thermal Print Head

Thermal Print Head are widely used in inkjet printers, especially in popular home and office models. They work by heating the ink rapidly until it forms a bubble. This bubble then expands and bursts, forcing a droplet of ink through the nozzle onto the paper.

This technology allows for fast printing at a relatively low cost, making it ideal for users who need efficiency without sacrificing quality. However, thermal Print Head can wear out over time due to constant heating, so regular maintenance and using the correct ink type are essential to extend their lifespan.

Piezoelectric Print Head

Unlike thermal Print Head, piezoelectric Print Head rely on small crystals that change shape when electricity passes through them. This movement forces the ink through the nozzle in precise, controlled drops.

The main advantage of piezoelectric technology is durability. Since there is no heating involved, these Print Head last longer and can handle a wider variety of inks, including those used for specialty printing like posters or labels. They’re commonly found in higher-end printers designed for professional use.

Continuous Inkjet Print Head

Continuous inkjet (CIJ) Print Head are often used in industrial and commercial printing environments. They continuously spray a stream of ink, but only certain drops are directed onto the paper to form the image while the rest are recycled back into the system.

This technology enables extremely high-speed printing on a wide range of materials, including packaging labels, barcodes, and signage. However, CIJ systems tend to be more expensive and require specialized maintenance compared to standard inkjet printers.

Drop-on-Demand Print Head

Drop-on-demand (DOD) Print Head, as the name suggests, release ink only when needed rather than continuously. This makes them efficient and less wasteful compared to continuous inkjet systems.

They are popular in both home and office printers because they balance cost, print quality, and ease of maintenance. With proper care, DOD Print Head can deliver crisp, high-resolution prints for years without frequent replacement.

Types of Print Head and Their Key Features

| Printhead Type | Technology Used | Key Advantages | Common Applications | Maintenance Level |

|---|---|---|---|---|

| Thermal Print Head | Heat creates ink bubbles | Fast, low-cost printing | Home & office inkjet printers | Moderate – heat wears out parts over time |

| Piezoelectric Print Head | Piezo crystals push ink droplets | Long lifespan, supports various ink types | Professional & commercial printers | Low – durable, fewer replacements needed |

| Continuous Inkjet Print Head | Continuous ink stream, selective drops | Extremely high-speed printing | Industrial packaging, barcodes, labeling | High – requires regular system upkeep |

| Drop-on-Demand Print Head | Ink released only when needed | Efficient, less ink waste | Home, office, and small business printers | Low – simple cleaning, minimal upkeep |

Printhead Materials and Manufacturing

The materials and manufacturing techniques behind a printhead are as important as its design. They determine not only print quality but also how long the printhead lasts before it needs cleaning or replacement.

Common Materials Used in Print Head

Print Head must withstand heat, friction, and exposure to ink chemicals without losing performance. That’s why manufacturers carefully choose materials based on durability, precision, and resistance to wear and tear.

Some of the most common materials include:

- Ceramics: Used mainly for the heating elements in thermal Print Head. Ceramic materials can handle extreme heat cycles while maintaining structural integrity, making them ideal for precision heating and cooling.

- Metals (e.g., Stainless Steel, Aluminum): The nozzles and structural components often use metal because it provides strength and corrosion resistance. Stainless steel nozzles, for example, resist clogging and wear better than cheaper alternatives.

- Heat-Resistant Polymers: Certain polymers are used for parts that don’t require metal strength but still need chemical resistance. These lightweight materials help reduce manufacturing costs while keeping performance stable.

- Piezoelectric Crystals: In piezoelectric Print Head, thin layers of special crystals respond to electrical signals, flexing to push ink droplets out with extreme precision.

Using high-quality materials ensures that the printhead can handle thousands of pages without degrading in performance.

How Manufacturing Affects Printhead Durability

Beyond the materials themselves, the way a printhead is manufactured plays a major role in its lifespan and reliability.

- Low-Cost Print Head: Budget printers often use mass-produced Print Head with simpler construction and less strict quality control. These models might use lower-grade metals or thinner coatings, which can wear out faster or clog more easily. As a result, they may require more frequent maintenance or replacement after heavy use.

- Premium Print Head: High-end printers use precision manufacturing methods such as laser drilling for nozzles and multi-layer coatings for ink channels. This creates tighter tolerances, smoother ink flow, and higher resistance to heat damage. Some premium Print Head also undergo individual testing to ensure uniform droplet size and firing accuracy before leaving the factory.

The difference is clear when comparing print quality and lifespan: a premium printhead can deliver sharper details and last much longer, making it a better investment for professional printing needs.

Common Printhead Problems and How to Fix Them

Even the most advanced Print Head can face problems over time. Issues like clogging, misalignment, or ink leakage often frustrate users because they directly affect print quality. Understanding these problems and how to fix them can save time, money, and prevent unnecessary replacements.

Clogged Nozzles and Cleaning Tips

Clogged nozzles are among the most common printhead problems. They occur when dried ink or dust blocks the tiny openings in the printhead, resulting in streaky or faded prints. Most printers have a built-in cleaning function that forces ink through the nozzles to clear blockages.

For stubborn clogs, manual cleaning may be necessary. This involves removing the printhead (if detachable), soaking it in a cleaning solution, or using a specialized printhead cleaning kit. Regular cleaning every few weeks can prevent clogging and ensure smooth operation.

Printhead Alignment Issues

When text or images look skewed, blurry, or doubled, it’s often a printhead alignment issue. Misalignment can happen due to mechanical vibrations, frequent paper jams, or after replacing ink cartridges.

Most printers include an automatic alignment tool accessible through the printer’s control panel or software. If that doesn’t solve the problem, manual alignment with calibration sheets can help restore print accuracy.

Ink Leakage and Smudging Problems

Ink leakage inside the printer can stain pages, waste ink, and even damage internal components. It often happens when the printhead is cracked, improperly installed, or the cartridges are overfilled.

To fix this, inspect the printhead and cartridges regularly. Reinstall or replace faulty components, and always use recommended ink types to prevent chemical reactions that may cause leaks. Keeping the printer clean also reduces the risk of smudging issues.

Printhead Maintenance Guide

Proper maintenance is the key to extending the life of your printhead and ensuring consistent print quality. Neglecting care can lead to clogging, poor prints, and even permanent damage. The good news is that with a few simple habits, you can keep your printhead in top shape for years.

Routine Cleaning Practices

Routine cleaning prevents dried ink from blocking the nozzles. Most modern printers have a built-in cleaning function accessible through the printer settings or control panel. Running this function once or twice a month keeps the nozzles clear and prevents minor blockages from turning into bigger issues.

For users who print less frequently, manual cleaning might be necessary. This involves carefully removing the printhead (if removable) and soaking it in a recommended cleaning solution to dissolve dried ink. Always follow the printer manufacturer’s guidelines to avoid damaging delicate components.

Recommended Cleaning Kits and Tools

Specialized cleaning kits are available for most popular printer brands. These kits usually include cleaning fluid, syringes, and lint-free cloths designed specifically for Print Head. Using the right tools prevents accidental damage and ensures effective cleaning.

Some users try DIY solutions like warm distilled water, but commercial cleaning fluids are formulated to dissolve stubborn ink residues without harming the printhead’s electronics. Investing in a proper cleaning kit can save you from costly replacements later on.

Preventive Maintenance for Long-Term Use

Prevention is always better than repair. Printing a test page every few days keeps the ink flowing and prevents it from drying inside the nozzles. Storing your printer in a dust-free, moderate-temperature environment also helps protect the printhead.

Additionally, always use high-quality ink cartridges compatible with your printer model. Low-quality or counterfeit ink can clog nozzles faster and even corrode the printhead’s internal parts. Spending a little more on the right ink can extend the printhead’s lifespan significantly.

When to Replace Your Printhead

No matter how well you maintain a printhead, there comes a time when cleaning and repairs just won’t restore print quality. Recognizing the right moment to replace the printhead saves both time and frustration while keeping your printer in optimal condition.

Signs That Indicate Replacement

Persistent printing problems often point to a printhead that needs replacing. Common symptoms include streaks or missing lines on every page, even after multiple cleanings. Another red flag is recurring alignment errors that persist despite recalibration attempts.

In some cases, the printer itself may display an error message indicating a damaged or worn-out printhead. Ignoring these signs can lead to more expensive printer repairs or complete device failure in the long run.

Choosing the Right Replacement Printhead

Not all Print Head are interchangeable. Each printer model typically requires a specific printhead designed for its hardware and ink type. Using the wrong printhead can cause compatibility issues, poor print quality, or even hardware damage.

When buying a replacement, always refer to your printer’s manual or the manufacturer’s official website for compatible part numbers. Genuine Print Head may cost more than third-party options, but they usually last longer and come with proper warranty support.

Cost Considerations: Repair vs Replacement

Replacing a printhead isn’t always the first solution. In many cases, repairing or cleaning it might be enough to restore performance. However, there are times when replacement becomes the more cost-effective choice. Understanding the financial aspects helps users make smart decisions.

Comparing Repair Costs vs Buying New

Repairing a printhead usually costs less upfront, especially if the problem is minor like clogged nozzles or slight alignment issues. Cleaning kits and basic maintenance tools are affordable and widely available for most printer models.

On the other hand, replacement costs vary depending on the printer type. For entry-level printers, a new printhead can sometimes cost nearly as much as a new printer itself. In such cases, buying a new device might be the smarter financial decision.

How to Save on Printhead Expenses

To minimize expenses, start with preventive maintenance. Regular cleaning reduces the need for costly repairs or replacements. Also, compare prices from different suppliers but prioritize genuine parts to avoid compatibility problems.

Another tip is to monitor printer usage carefully. High-volume users should consider investing in printers with longer-lasting, high-quality Print Head. While the initial cost may be higher, the lower maintenance expenses in the long run often make it worthwhile.

Conclusion

Print Head are the heart of any printer. From the way ink flows through channels to the precision of nozzle firing, every part of the printhead influences print quality, speed, and reliability. Understanding its components, materials, and how it works helps users take better care of their printers, choose the right models for their needs, and troubleshoot problems more effectively.

Whether you’re a home user or running a small office, keeping your printhead clean, using quality ink, and following the manufacturer’s maintenance tips will keep your printer performing at its best for years.

FAQs About Print Head

What is the main function of a printhead?

A printhead controls how ink moves from the cartridges to the paper with precision, ensuring accurate colors, sharp text, and clean images.

How often should I clean my printer’s printhead?

Cleaning frequency depends on usage. For regular users, a monthly cleaning routine is enough. For occasional printing, clean the printhead whenever you see streaks or missing lines.

Can I replace a printhead myself?

Yes, many printers allow users to replace Print Head easily. However, always follow the manufacturer’s instructions to avoid damaging the printer.

What causes printhead clogs?

Common causes include dried ink, using low-quality ink, or leaving the printer unused for long periods. Storing the printer properly and printing regularly helps prevent clogs.

Do premium Print Head really last longer?

Yes. Premium Print Head often use better materials and stricter manufacturing standards, which means they resist wear, heat, and clogging better than budget options.